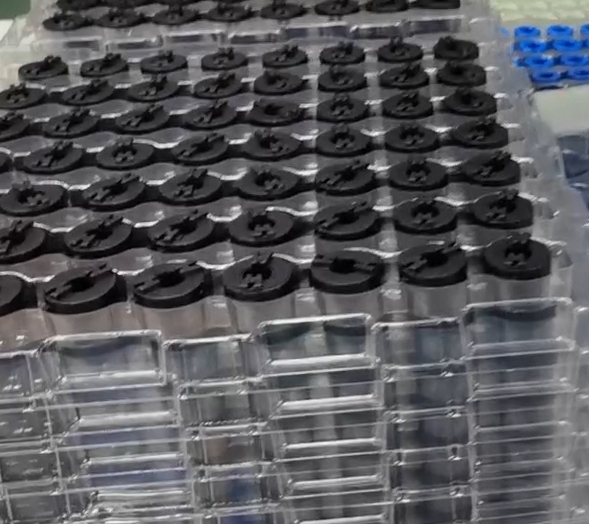

Dongguan JH Amorphous is proud to announce a successful mass production launch of a custom-designed amorphous magnetic ring assembly for a leading Italian electronics component manufacturer. This milestone comes after a rigorous two-year joint validation and testing process, which included mechanical reliability assessments, magnetic performance testing, and long-term environmental trials.

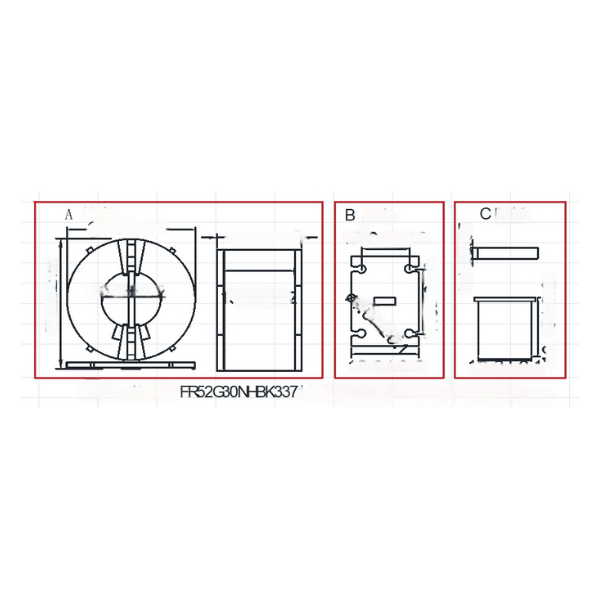

The solution includes a precision-engineered magnetic core housed in a three-part assembly: protective casing (A), base (B), and insulating plate (C). All dimensions were strictly controlled to meet the customer's specification drawings, ensuring compatibility with automated winding and assembly lines. The part number for this solution is JH221212-23285, as defined in our APQP (Advanced Product Quality Planning) system.

During this project, Dongguan JH Amorphous successfully passed the IATF16949 quality management system certification, a globally recognized standard for automotive and high-reliability electronics industries. This certification further reinforced the customer’s confidence in our production capability, process control, and quality assurance systems.

The client expressed high satisfaction with both the magnetic performance consistency and mechanical assembly tolerances of our final product. The collaboration also showcased our ability to adapt to European project standards, deliver accurate documentation (such as APQP control plans), and support long-cycle verification efforts from prototype through to mass production.

This project marks another important step in Dongguan JH Amorphous’s commitment to serving global customers with high-reliability soft magnetic core solutions—from engineering support and prototyping to certified mass production.