2025 Global Soft Magnetic Materials Price Matrix and Technical Evolution Depth Research Report

Dec 25, 2025

Table of Contents

1. Market View ..................................................................................................... 2

1.1 Global Drivers: Power Electronics, EV, 5G, and AI ......................................... 2

1.2 Market Size Projections: 2025–2029 CAGR Analysis ..................................... 2

1.3 Material Selection as a Key Variable in Supply Chain Optimization ............... 2

2. 2025 Mainstream Soft Magnetic Core Price Benchmarks ........................... 3

2.1 Standardized Price Matrix for Industrial-Grade Bulk Orders ........................... 3

2.2 Application Fields and Core Performance Advantages by Material .................4

4. Iron-Based Nanocrystalline Cores: The High-Efficiency Benchmark ........ 5

5. Ferrite Materials: Cornerstones of High-Frequency Domains .................... 6

6. Sendust Cores: Balancing Performance and Stability ................................ 7

7. Permalloy: Noble Materials for Precision and Shielding ............................. 8

8. The Market Anchors: Silicon Steel and Amorphous Alloys ........................ 9

9. Macro Drivers of Core Pricing in 2025 ......................................................... 10

10. Technical Parameter Comparison (2025 Summary Table) ...................... 11

11. Conclusion and Industry Outlook .............................................. ............... 11

12. About JH Amorphous .................................................................................. 12

13. References .................................................................................................... 12

If you are interested full report, contact julia@amorphousoem.com.

Market View

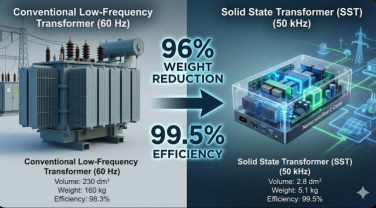

The rapid evolution of global power electronics, electric vehicles (EVs), 5G communications, AI and renewable energy infrastructure has placed unprecedented demands on the performance and cost of magnetic materials.

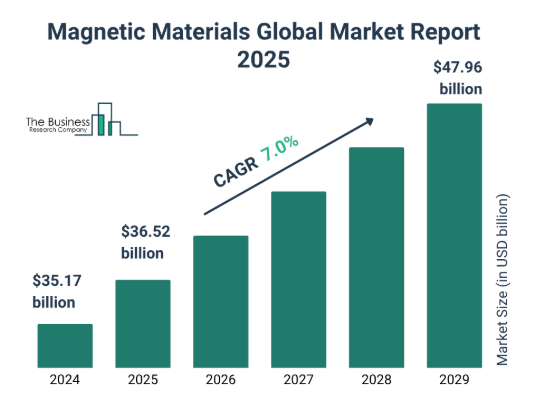

In the market of 2025, soft magnetic materials are not only the core carriers for energy conversion and signal processing but also critical variables in supply chain cost optimization. According to the latest industry estimates, the global magnetic materials market size reached approximately USD 36.52 billion in 2025 and is expected to maintain a CAGR of 7% to 8.64% over the next decade. This growth is primarily driven by the extensive penetration of soft magnetic materials in electronic devices and power generation, where material selection directly dictates system power density and thermal management strategies.

Soft magnetic materials encompass a variety of categories, ranging from low-cost silicon steel to high-performance iron-based nanocrystalline, ferrites, Permalloy, and high flux cores.

In 2025, the market focuses not just on raw material costs but emphasizes the integrated cost-benefit ratio brought by technological advancement.

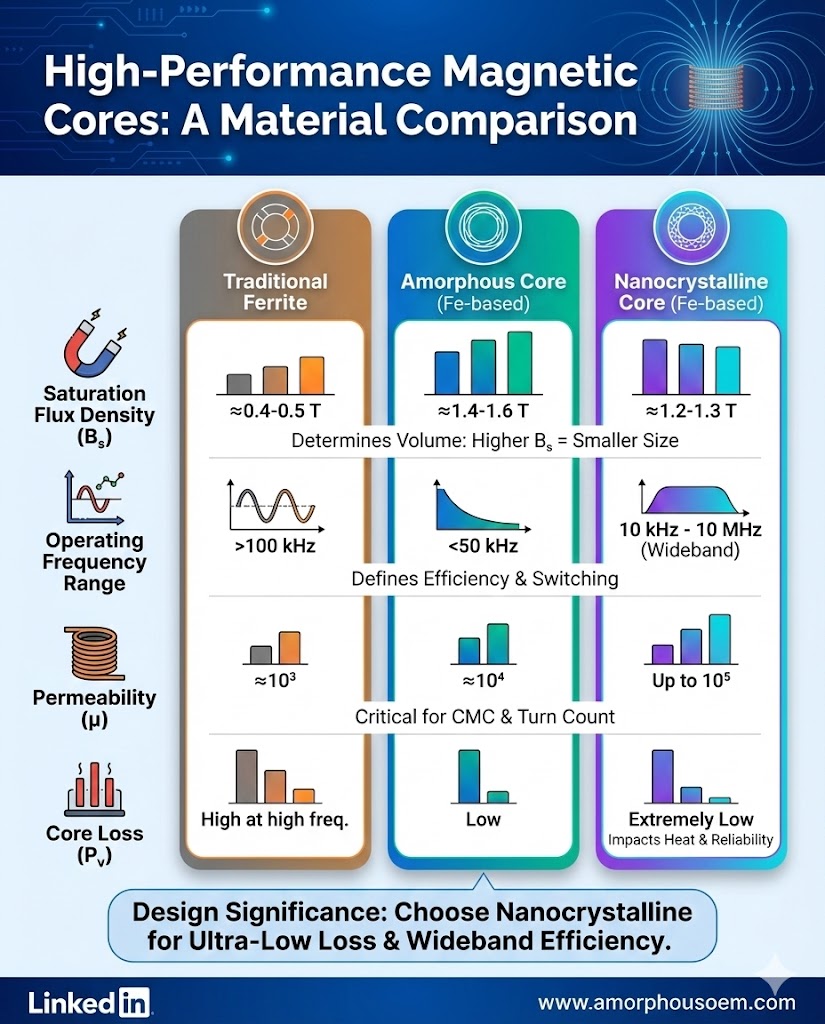

For instance, the core loss of iron-based nanocrystalline materials at 100 kHz is nearly 1,000 times lower than that of traditional silicon steel. This generational performance gap means that in high-frequency applications, even with a higher unit price, nanocrystalline materials significantly improve overall cost-performance by enabling system-level lightweighting and reducing cooling costs.

Overview of Mainstream Soft Magnetic Core Price Benchmarks (2025)

Before analyzing specific materials, it is essential to establish a standardized price comparison matrix. The following data is based on average quotes for global industrial-grade bulk orders and suppliers investigation in China, Ex work, with units unified in USD/Kg to reflect the relative market positioning of different materials. The price is for reference only, will be different based on QTY. , shapes, electric specifications and business terms.

Material Type

Price Range

(USD/Kg)

Main Application Fields

Core Performance Advantages

GOES (Grain-Oriented Electrical Steel)

1.15 – 4.06

Large transformers, grid infrastructure

High saturation induction (Bs), low cost

CRNGO (Non-Oriented Electrical Steel)

1.15 – 6.00

Electric motors, generators

Isotropic properties, high-speed efficiency

Iron-based Amorphous Cores

2.50 – 8.00

Distribution transformers, reactors, motors

Extremely low standby loss, 50Hz~1KHz

Iron-based Nanocrystalline

6.00– 45.00

EV charging piles, inverters, EMC filters, UPS, Data Center, SMPS

High permeability, wide frequency range

(1K~100K Hz)

Mn-Zn Ferrite

1.20 – 6.00

Switched-mode power supplies (SMPS), UPS

Extremely high resistivity, mature process

<5MHz

Ni-Zn Ferrite

2.20– 12.00

High-frequency EMI, RF applications

Ultra-high frequency stability 2~70MHz

Sendust Powder

2.80 –6.50

Powder metallurgy feedstock

>8kHz

Permalloy (1J50/1J85)

30.0- 142.00

Precision sensors, magnetic shielding

20~30kHz

Iron-Based Nanocrystalline Cores: The Performance Benchmark for High-Efficiency Power

Iron-based nanocrystalline materials represent the pinnacle of contemporary soft magnetic technology. The production involves spraying a molten iron-based alloy at a rate of 10^6 K/s onto a high-speed rotating cooling roll to form an amorphous ribbon only 12 to 30 microns thick, followed by precise heat treatment to induce the precipitation of grains 10 to 15 nanometers in diameter. This unique dual-phase structure grants the material high saturation magnetic induction (Bs 1.25 T) and ultra-high initial permeability (80,000 ~190,000).

Cost Composition and Market Pricing

In 2025, the price of nanocrystalline cores is heavily influenced by production thickness, ribbon width, and post-processing (such as core cutting or coating). Industrial bulk quotes for finished cores typically range between USD 6.00 and 45.00 per kg. If examining only the raw material ribbons (e.g., the 1K107 series), the price range is more concentrated between USD 6 and 13.48 per kg.

The market premium for nanocrystalline cores in 2025 stems from their complex processing chain. Cut Core processes, which significantly improve assembly efficiency and optimize magnetic leakage, often command a unit price more than 50% higher than toroidal wound cores.

Furthermore, because nanocrystalline ribbons are extremely thin and brittle, the requirements for insulation coatings and protective casings are stringent, forming a non-negligible part of the finished unit price.

The Economic Logic: Nanocrystalline vs. Traditional Materials

From a techno-economic perspective, although the unit price of nanocrystalline is 5 to 10 times that of ordinary silicon steel, its application in weight-sensitive sectors like EV traction inverters can reduce transformer volume by 50% and weight by 40%. This "volume-for-efficiency" logic has become highly attractive under 2025 high-energy-efficiency standards. Research shows that at 100 kHz, the loss per unit volume of nanocrystalline cores is far lower than that of Mn-Zn ferrites, making it nearly the only viable solution for megawatt-level high-power high-frequency transformers.

Macro Drivers Influencing Core Pricing in 2025

1. Chinese Supply Chain Dominance: China remains the production hub, accounting for 94.67% of global trade in iron-based nanocrystalline. This concentration makes global prices highly dependent on Chinese electricity costs and export policies.

2. Trade Barriers: Plans by the US to impose 25% to 40% tariffs on metals from over 150 countries starting August 2025 have caused sharp regional price disparities for identical specifications.

3. Energy Intensity: Sintering ferrites and refining silicon steel are energy-intensive. Fluctuations in industrial electricity prices in Europe and SE Asia provide strong support for manufacturing costs.

Read More