Sep 11, 2025

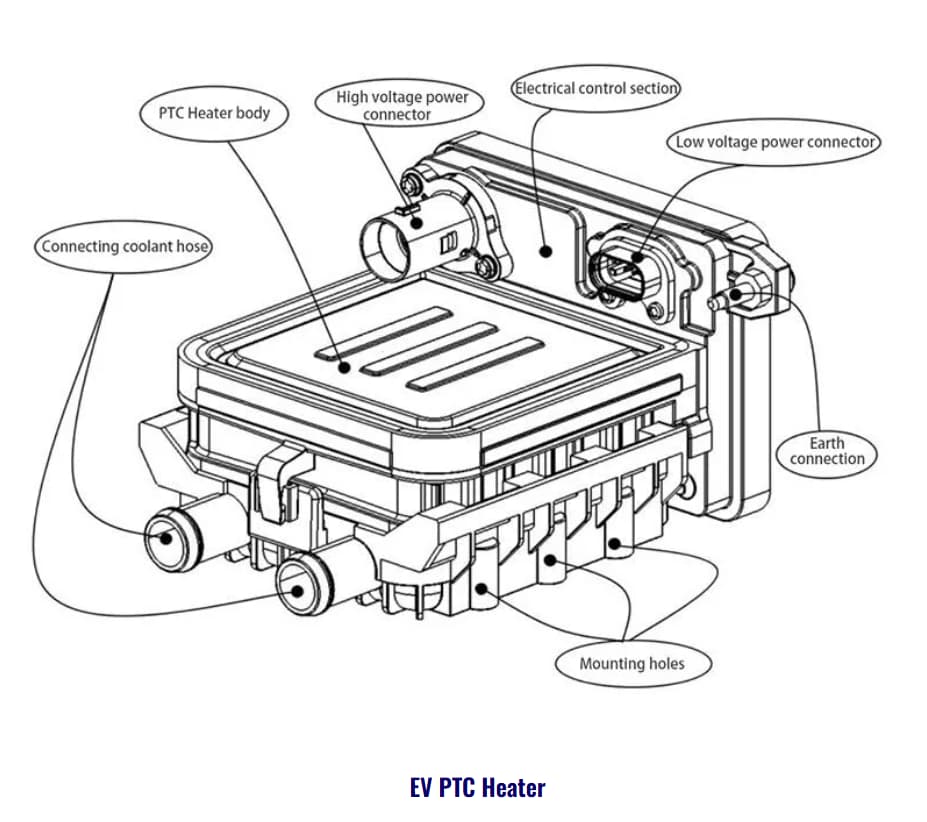

In electric vehicles (EVs), passenger comfort and energy efficiency are key design considerations. High voltage PTC (Positive Temperature Coefficient) heaters are widely used for cabin heating and battery thermal management. However, many engineers face a persistent issue: excessive noise and EMI interference generated by PTC heater modules.

Why Do PTC Heaters Generate Noise?

High voltage PTC heaters operate at 400V–800V and involve fast switching electronics. These factors can lead to multiple noise sources:- EMI Noise: Switching spikes from MOSFETs/IGBTs cause common mode and differential mode interference.- Buzzing & Humming: Magnetostriction and vibration effects.- High-Frequency Whine: Audible tones caused by poor filtering or PCB layout resonances.

Traditional Solutions and Their Limits

Engineers have tried:- Ferrite cores (low cost but limited performance at high frequencies)- Shielding and PCB layout optimization- Oversized inductors (increase cost and weight)

Why Nanocrystalline Cores Are the Answer

Nanocrystalline magnetic cores offer:- High Permeability (μ up to 80,000) for EMI suppression- Low core loss at high frequencies- Compact size for space-saving- Proven use in EV chargers, DC/DC converters, and now PTC heaters

Case Example: EV Heater Noise Suppression

A Tier-1 automotive supplier struggled to pass EMC testing for their high voltage PTC heater. The noise spectrum showed severe issues at 150 kHz–300 kHz and 30 MHz–110 MHz, where ferrite materials are less effective. After replacing ferrite beads with nanocrystalline toroidal cores (OD 4 × ID 2.5 × H 2.5 mm):- EMI noise across these bands was successfully suppressed- Overall EMI reduced by 40%- Temperature rise decreased by 15 °C under full load- Compact design enabled 30% space savingMost importantly, the heater module passed EMC certification and entered mass production.

High voltage PTC heaters are critical in EVs for cabin comfort and battery thermal management. Engineers facing EMI or acoustic noise issues should consider nanocrystalline cores as a proven, scalable solution. Our team provides samples with IATF 16949 standard, technical support, and long-term supply to help your project succeed.

Read More