Amorphous vs. Nanocrystalline Cores: The Critical Selection for EVs and PV Inverters

The relentless push toward electrification—from high-performance Electric Vehicle (EV) power control units to grid-optimizing Photovoltaic (PV) inverters—is uniformly demanding components that can handle higher switching frequencies, increased power densities, and extreme efficiency. When system frequencies push past conventional limits, traditional ferrite materials often become the bottleneck, introducing significant losses. For R&D engineers, selecting the right soft magnetic material is not just a component swap; it's a critical decision that dictates the product's performance, size, and ultimate cost. Amorphous and Nanocrystalline materials are the key contenders in this high-stakes selection battle.

Both Amorphous and Nanocrystalline cores achieve their characteristic exceptionally high permeability and ultra-low core loss due to their unique microstructures:

Amorphous Cores: The atoms are in a disordered, non-crystalline state, which eliminates grain boundaries and effectively minimizes eddy current losses. Typically iron-based, amorphous materials boast a high Saturation Magnetic Flux Density (Bs) (up to 1.6T), making them highly suitable for high-current, high-power applications where minimizing volume is paramount.

Nanocrystalline Cores: These are created by subjecting amorphous alloys to a precisely controlled annealing process, resulting in ultra-fine grains (only 10 nanometers in size). This structure nearly eliminates effective magnetic anisotropy, leading to the lowest loss and highest permeability among soft magnetic materials, especially across the mid-to-high frequency spectrum.

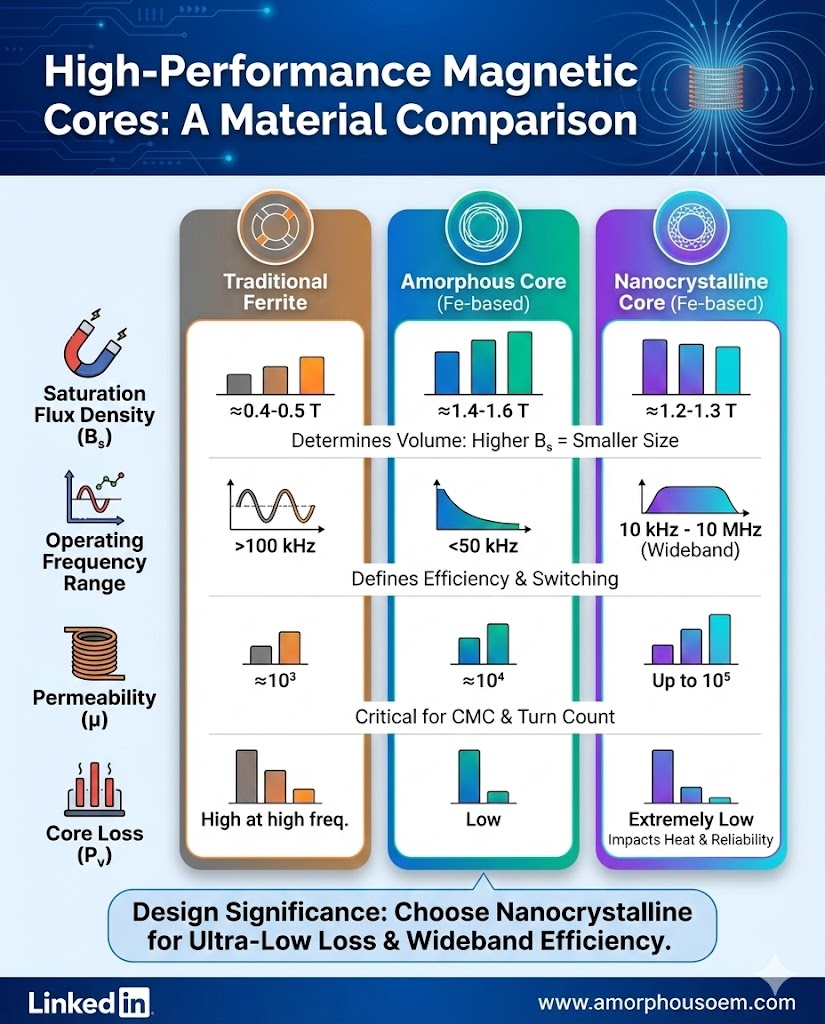

Here is a quick reference table comparing key parameters for engineers:

| Performance Parameter | Traditional Ferrite | Amorphous Core (Fe-based) | Nanocrystalline Core (Fe-based) | Design Significance |

| Saturation Flux Density (Bs) | 0.4-0.5T | 1.5-1.6T | 1.2-1.3T | Determines transformer/inductor volume (Higher Bs allows smaller size). |

| Operating Frequency Range | Mid-to-High Freq. (>100kHz) | Mid-to-Low Freq. (<50 kHz) | Wideband (10 kHz to 10 MHz) | Defines system efficiency and switching capability. |

| Permeability (ui) | approx 1000~5000 | approx 10000~50000 | Up to 190000 | Critical for common mode choke effectiveness and turn count. |

| Core Loss (Pv) | High (at high frequencies) | Low | Extremely Low | Directly impacts heat generation and system reliability. |

EV Power Control: The Key to Cooling and Filtering

As On-Board Chargers (OBCs) and DC-DC converters push past 100kHz, the ultra-low loss of nanocrystalline materials makes them the preferred choice for main transformers and resonant inductors, significantly reducing thermal dissipation and boosting efficiency.

For Electromagnetic Compatibility EMC, EV control units generate substantial high-frequency noise. Nanocrystalline cores, with their exceptionally high permeability, are the ideal material for manufacturing high-performance Common Mode Chokes (CMCs), effectively suppressing noise across the 10 kHz to 10 MHz range.

PV Inverters: Balancing Power and Efficiency

Amorphous alloys are frequently used in large-current filter inductors within high-power PV systems. Their high Bs and excellent low-frequency loss characteristics allow them to handle large current swings in a smaller form factor.

In modular inverters targeting higher power density, Nanocrystalline is adopted in high-frequency transformers and CMCs to maximize conversion efficiency and overall system compactness.

While Amorphous cores remain vital in large-power filtering and lower-frequency applications due to their high saturation flux density and cost advantages, Nanocrystalline cores are rapidly becoming the default solution for high-frequency power electronics driven by SiC/GaN platforms. This shift is driven by their ultra-low loss and superior permeability across a wide bandwidth. Engineers must precisely balance operating frequency, thermal limits, and power density targets when finalizing their material selection.

The future will demand even higher system frequencies, placing greater pressure on soft magnetic materials. Continuous optimization of nanocrystalline core performance will be central to ensuring the long-term reliability of high-performance power electronics systems.

Is your next high-frequency, high-power project bottlenecked by magnetic core selection?

As a specialized manufacturer of high-performance Amorphous and Nanocrystalline soft magnetic materials, Dongguan JH Amorphous controls the core technology from ribbon to precise thermal processing. We provide customized core solutions tailored specifically to your OBC, DC-DC, or PV inverter design needs, guaranteeing efficiency improvements and size optimization.

We invite you to visit our website today or send your detailed design specifications to our engineering team. Let our professional soft magnetics experts provide you with the selection advice and sample support you need to unlock the next level of performance for your product!