Jan 27, 2026

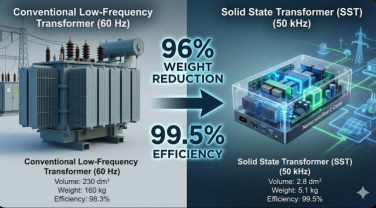

In the race to design next-generation Solid State Transformers (SST) and EV power units, the goal is audacious: a 96% reduction in weight.

To achieve this massive downsizing, engineers are pushing switching frequencies to 50 kHz and beyond. But this creates a formidable thermal barrier. As every power electronics engineer knows, high frequency usually comes with a heavy penalty: Heat.

How do you balance the need for high magnetic flux density (to keep size small) with the need for low core losses (to keep heat manageable)? The 2025 material data reveals that traditional materials are no longer sufficient. It is time to look at the Nanocrystalline solution.

The High-Frequency Trade-off: A Material Dead End

At 50 kHz, the choice of magnetic core material dictates the success or failure of the thermal management system. Let’s look at the data:

1. Silicon Steel: The Overheating GiantSilicon Steel boasts an impressive Saturation Flux Density(Bs)of 2.03 T, which is great for size reduction in theory.

The Dealbreaker: At 50 kHz, Silicon Steel suffers from disastrous eddy current losses—approximately 200 W/kg. It turns your transformer into a heater, requiring bulky cooling systems that negate any size savings.

2. Ferrite: The Bulky CompromiseFerrite is the traditional "safe choice" for high frequency due to its high resistivity and low loss.

The Dealbreaker: Its Saturation Flux Density is pitifully low, hovering around 0.4 T. To handle high power, you need a massive cross-sectional area, resulting in a bulky core that makes the "96% weight reduction" goal impossible.

The Nanocrystalline Advantage: Breaking the Trade-off

Nanocrystalline C-Cores have become the industry standard for SSTs because they occupy the "Goldilocks Zone" of magnetic properties. They don't force you to choose between size and efficiency—they deliver both.

According to recent comparative testing at 50 kHz:

With a saturation level more than 3x higher than Ferrite, Nanocrystalline cores allow for compact, high-power designs that fit within tight mechanical constraints. Some advanced grades even reach 1.4 T.

Incredible Efficiency (2-5 W/kg):While Silicon Steel generates ~200 W/kg of heat, Nanocrystalline generates only 2-5 W/kg. This drastic reduction in core loss means simpler cooling, higher system reliability, and significantly higher efficiency.

Extreme Permeability:With permeability up to 190,000, these cores ensure superior impedance performance even under high-frequency stress, minimizing leakage inductance.

Conclusion: Don't Let the Core Compromise the Design

Achieving the weight and efficiency targets of modern Solid State Transformers requires a material that can withstand the stress of 50 kHz without melting down.

At Dongguan JH Amorphous, we specialize in precision-wound Nanocrystalline solutions that are engineered to solve this exact thermal dilemma. Whether for EV on-board chargers or grid-tied SSTs, we deliver the balance your engineering demands.

Optimal Flux Density(Bs=1.25T):With a saturation level more than 3x higher than Ferrite, Nanocrystalline cores allow for compact, high-power designs that fit within tight mechanical constraints. Some advanced grades even reach 1.4 T.

Incredible Efficiency (2-5 W/kg):While Silicon Steel generates ~200 W/kg of heat, Nanocrystalline generates only 2-5 W/kg. This drastic reduction in core loss means simpler cooling, higher system reliability, and significantly higher efficiency.

Extreme Permeability:With permeability up to 190,000, these cores ensure superior impedance performance even under high-frequency stress, minimizing leakage inductance.

Conclusion: Don't Let the Core Compromise the Design

Achieving the weight and efficiency targets of modern Solid State Transformers requires a material that can withstand the stress of 50 kHz without melting down.

At Dongguan JH Amorphous, we specialize in precision-wound Nanocrystalline solutions that are engineered to solve this exact thermal dilemma. Whether for EV on-board chargers or grid-tied SSTs, we deliver the balance your engineering demands.

Read More