Market Insight: Silicon Steel vs. Nanocrystalline – The "50% Diet" for Your High-Power Transformer

In the modern power electronics landscape, "Bigger" is no longer "Better." It is just... bigger.

For decades, Silicon Steel sheets have been the backbone of the transformer industry. However, as operating frequencies rise and the demand for compact, portable power units explodes, silicon steel is hitting a physical wall.

Are you still struggling with bulky, heavy transformers that complicate your thermal management?

Today, we analyze the market shift toward Nanocrystalline C-Cores and how this material upgrade is revolutionizing designs in high-stakes fields like Medical X-Ray and Induction Heating.

Engineers face a dual challenge: increasing power density while reducing footprint.

The Silicon Steel Trap: To handle high power without saturation, silicon steel transformers require significant mass. At higher frequencies (10kHz+), their core losses skyrocket, turning your transformer into a heater.

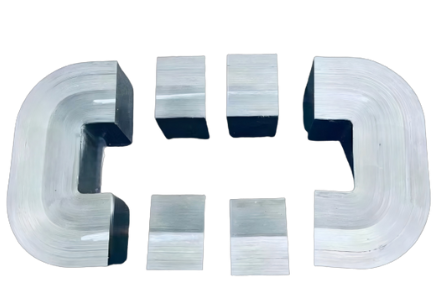

The Nanocrystalline Solution: By switching to Nanocrystalline C-Cores, you aren't just changing materials; you are changing the physics of your design.

Based on data from our European partnerships, replacing Silicon Steel with Nanocrystalline C-Cores yields immediate, measurable results:

Weight & Volume Reduction (~50%):

Thanks to high saturation flux density (Bs = 1.25T)combined with high permeability, Nanocrystalline cores can handle the same power transfer in a package half the size and weight of a silicon steel equivalent.

Thermal Mastery:

Lower hysteresis and eddy current losses mean less heat generation. This allows engineers to downsize cooling systems (heatsinks/fans), further compounding the space savings.

1. Medical X-Ray Equipment

Modern medical imaging demands mobility. A portable X-Ray unit cannot carry a heavy iron block.

Insight: Nanocrystalline C-Cores allow for high-voltage pulse transformers that are lightweight enough for bedside mobile units, yet powerful enough for crisp imaging, all while maintaining strict stability.

2. Induction Heating Systems

These systems run at high frequencies to heat metals rapidly.

Insight: Standard cores struggle with the heat generated at these frequencies. Nanocrystalline cores thrive here, offering stable inductance and minimized losses, ensuring the energy heats the workpiece, not the transformer.

Europe is known for the world's strictest industrial tolerances.

We are currently supplying these high-performance C-Cores to partners across Europe who demand:

Strict Tolerance Control: Precision cutting to ensure predictable air gaps.

Reliable Magnetic Properties: Consistency from batch to batch.

Conclusion

If your design goals involve "Compact," "Efficient," or "Cool," Silicon Steel is likely holding you back. The transition to Nanocrystalline is not just an option; it is the industry standard for next-generation power topology.