How does the Core Materials Define Performance for Common Mode Choke?

Jul 29, 2025

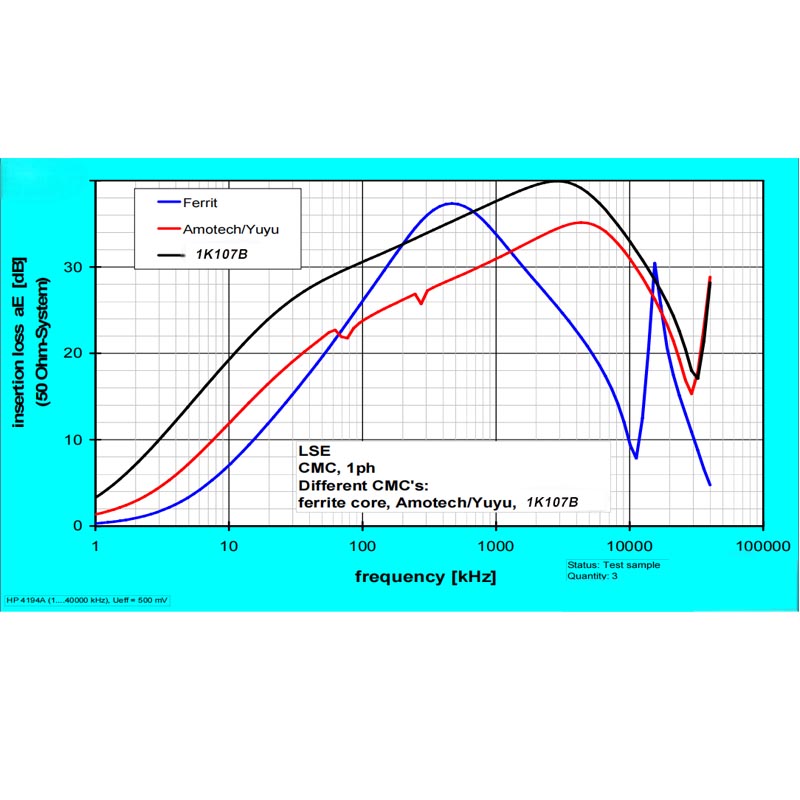

In today’s fast-evolving electronics landscape, electromagnetic interference (EMI) poses a serious threat to system reliability and signal integrity. Common mode chokes (CMCs) are indispensable in suppressing such interference—and at the heart of every CMC lies the magnetic core. Ferrite and nanocrystalline materials are the two leading core options, each offering distinct advantages.

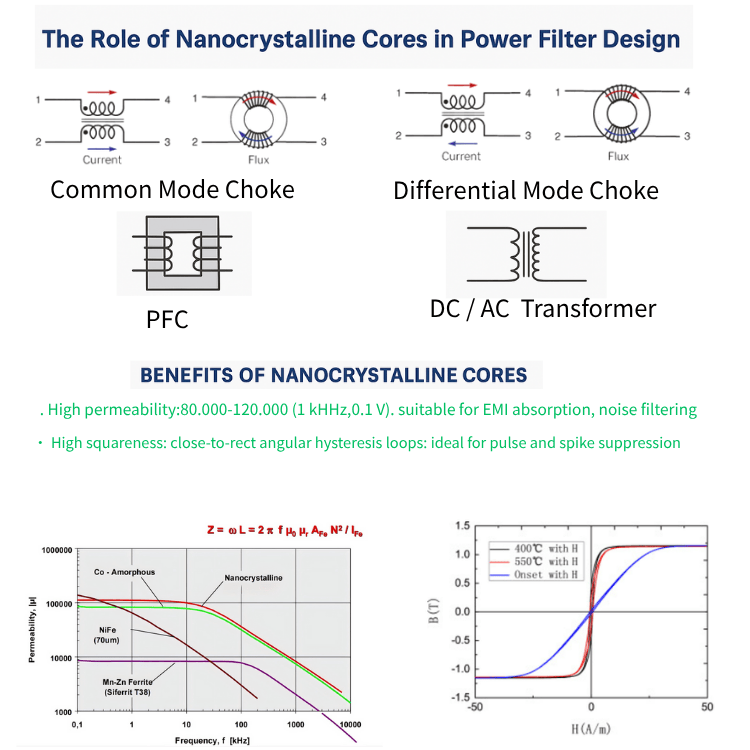

How Do Common Mode Chokes Work?

A common mode choke typically consists of two windings wrapped around the same magnetic core. When common mode noise currents flow through these windings in the same direction, their magnetic fields reinforce each other, generating high impedance that blocks the noise. In contrast, differential mode signals generate opposing magnetic fields that cancel out, allowing the desired signal to pass with minimal resistance.

Key parameters such as impedance, noise frequency range, and current-handling capacity are all fundamentally determined by the core’s magnetic properties.

Ferrite Cores: The Traditional, Cost-Effective Choice

Ferrite cores are ceramic materials made primarily from MnZn or NiZn compounds, with widespread use due to their mature manufacturing processes and good cost-performance ratio.

MnZn ferrites offer high initial permeability (typically 5,500–15,000) and work well up to 1–2 MHz.

NiZn ferrites, with lower permeability but higher resistivity, are suitable for higher frequency ranges—up to 5 MHz.

Ferrite cores generally have a saturation flux density between 0.3 and 0.49 Tesla. Their Curie temperature ranges from 120°C to 150°C, and permeability can fluctuate significantly with temperature changes. They also face high-frequency limitations due to Snoek’s limit, usually around 1 MHz for high-permeability MnZn ferrites.

Despite these constraints, ferrite cores are still widely used in power supplies, telecom systems, data lines, consumer electronics, SMPS, and variable frequency drives—offering low cost, light weight, and readily available options for general EMI suppression.

Nanocrystalline Cores: High-Performance EMI Suppression

Nanocrystalline cores are made from Fe-Si-Nb-Cu-B alloys processed through specialized field annealing techniques. The result is a material with magnetic properties far superior to ferrite.

These cores deliver:

Extremely high permeability (initial >80,000; max >600,000)

High saturation flux density (>1.2 Tesla)

Broadband impedance performance across 1 kHz to 20+ MHz

Exceptional thermal stability, maintaining performance from –40°C to 140°C, with minimal variation due to a high Curie temperature (>570°C)

Additionally, nanocrystalline cores allow size and weight reduction (up to 45% smaller and 47% lighter for equivalent performance), along with low core losses and minimal magnetostriction.

They are ideally suited for high-performance applications, including:

Electric vehicles (DC charging stations, traction inverters, XFC)

Renewable energy systems (solar inverters, energy storage)

Industrial automation (motor drives)

Power electronics (UPS systems, EMI filters, high-speed data equipment)

Ferrite vs. Nanocrystalline: Choosing the Right Core

Selecting between ferrite and nanocrystalline cores involves evaluating several factors: target noise frequency, impedance needs, current capacity, thermal requirements, size and weight constraints, and budget.

Ferrite cores are well-suited for lower frequency EMI suppression (up to 1–2 MHz) and are cost-effective for general applications.

Nanocrystalline cores excel in broadband noise suppression, high current handling, and thermal stability—making them ideal for compact, high-performance systems.

Although nanocrystalline cores have a higher upfront cost, their advantages in performance, miniaturization, and reliability often provide superior long-term value.

Feature

Nanocrystalline Cores (e.g., 1K107)

Ferrite Cores (e.g., Mn-Zn)

Material

Fe-Si-Nb-Cu-B (field-annealed ribbon)

MnZn or NiZn ceramic oxides

Permeability (µr)

Very High (>80,000 initial, >600,000 max)

High (1,500–10,000 initial)

Saturation Flux Density (Bs)

High (≥1.2 Tesla)

Moderate (~0.4–0.49 Tesla)

Optimal Frequency Range

Broadband (1 kHz–300+ MHz)

Narrower (MnZn up to ~1–2 MHz; NiZn up to several 100 MHz)

Temperature Stability

Excellent (–40°C to 140°C, Curie temp >570°C)

Moderate (µ varies with temp, Curie temp 120°C–150°C)

Size & Weight

Smaller and lighter (up to 45%/47% savings)

Bulkier for comparable performance

Key Advantages

Superior EMI suppression, thermal stability, miniaturization, customization

Cost-effective, widely available

Ideal Applications

EVs, renewable energy, inverters, high-speed data

Power supplies, telecom, data lines, consumer electronics

Dongguan JH Amorphous Co., Ltd. specializes in advanced amorphous and nanocrystalline soft magnetic cores. With extensive expertise in tailor-made magnet core solutions, we are uniquely positioned to assist designers and engineers in selecting the ideal core material to optimize their common mode choke solutions, ensuring peak performance and regulatory compliance for their specific applications .

Read More