Jul 23, 2025

With electric vehicles, solar inverters, and 5G power systems growing fast, one thing is clear: power filters are no longer optional. They're mission-critical.

EMI (electromagnetic interference) is a major headache in modern electronics. If you can’t control noise, you risk failing CE, FCC, or CISPR compliance — and losing the project.

So how is power filter design evolving? And why are more engineers switching to nanocrystalline magnetic cores?

Let’s break it down.

1. Why Power Filters Matter More Than Ever

The global EMI filter market is expected to hit $1.5 billion by 2030

Nanocrystalline core demand is growing fast — from $1.3B in 2023 to $2.8B by 2030

EV charging stations, solar power, telecom power modules — all need compact, high-performance filters

Designers must meet stricter EMC rules while shrinking size and boosting efficiency

2. What’s Changing in Power Filter Design

✅ Higher FrequenciesModern systems use SiC and GaN chips that switch at hundreds of kHz — even MHz. Ferrites can't keep up.

✅ Smaller FootprintDesigners want smaller filters, especially for EVs and telecom. You need materials that pack more power in less space.

✅ Tougher EMC RequirementsFilters now need 60dB+ noise reduction across 150kHz to 30MHz and beyond.

✅ Passing Certification Is HarderFailing EMC tests means delay, redesign, or lost business.

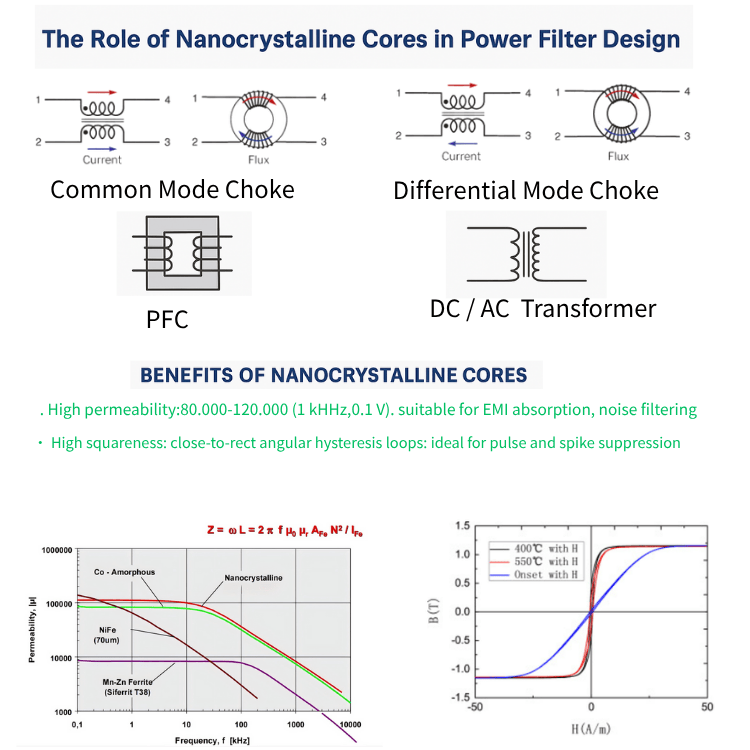

3. Why Nanocrystalline Cores Are the New Standard

Feature

Why It Matters

Ultra-high permeability (80k–120k @ 1kHz, 0.1V)

Absorbs EMI better, allows compact designs

High squareness ratio (Br/Bs ≈ 1)

Excellent spike and surge suppression

Low core loss at high frequencies

Runs cooler, saves energy

Stable under heat

Reliable even in harsh environments

Helps meet EMC standards

Easier CE/FCC/CISPR compliance

4. Where to Use Nanocrystalline Cores in Your Design

🔹 Common Mode ChokesPlaced on AC input to block common-mode noise→ Use toroidal nanocrystalline cores

🔹 Differential Mode FiltersPlaced after rectifiers or near outputs to block high-frequency switching noise→ Use gapped toroidal or cut cores

🔹 PFC InductorsPlaced in front of power factor correction stages to handle high current→ Use nanocrystalline C-cores or E-cores

🔹 Output Filters & TransformersPlaced near the load or in DC/DC converters→ Use custom-wound nanocrystalline cores

5. Real-World Advantages for Designers

✅ Reduce the number of filter stages✅ Shrink your filter size and weight✅ Improve system energy efficiency✅ Lower EMI and meet compliance faster✅ Design for tomorrow’s high-frequency needs — today

Ready to Try? Get Samples and Support Now

We are an experienced OEM/ODM manufacturer of nanocrystalline and amorphous magnetic cores, serving customers worldwide in EV, inverter, power supply, and telecom industries.

🌐 Website: www.amorphousoem.com📩 Email: julia@amorphousoem.com📱 WhatsApp: +86 13686646827

💡 Contact us for:✅ Free sample kits✅ Filter design tips✅ Custom core manufacturing

Let’s engineer better filters — together.

Read More