Aug 26, 2025

With the rapid growth of electric vehicles (EVs) and intelligent automotive systems, the demand for high-performance inductors has never been greater. Automotive electronics require components that deliver stable inductance, low power loss, and long-term reliability under harsh conditions. Among them, the 191125 size nanocrystalline magnetic core inductor stands out as an excellent solution for speed-limiting inductor applications, onboard chargers, and automotive power management modules.

This article provides a comprehensive overview of the product’s features, advantages, and application value in the evolving automotive industry.

1. What is the 191125 Size Nanocrystalline Core for Inductor?

The 191125 nanocrystalline magnetic core is designed bear core outside dia. 19mm, inner dia. 11mm, height 25mm, Fe-based nanocrystalline 1K107B material. At a working frequency of 100KHz, it delivers a stable inductance value ranging between 52μH and 73μH. The product is optimized for automotive-grade environments, ensuring consistent performance even under extreme conditions such as high temperature, vibration, and electromagnetic interference.

In automotive applications, speed-limiting inductors are critical to electromagnetic compatibility (EMC). They help suppress high-frequency noise and stabilize current flow, preventing malfunctions in sensitive electronic systems. By adopting nanocrystalline material, the 191125 inductor combines compact size with superior magnetic performance.

2. Advantages of Nanocrystalline Magnetic Core

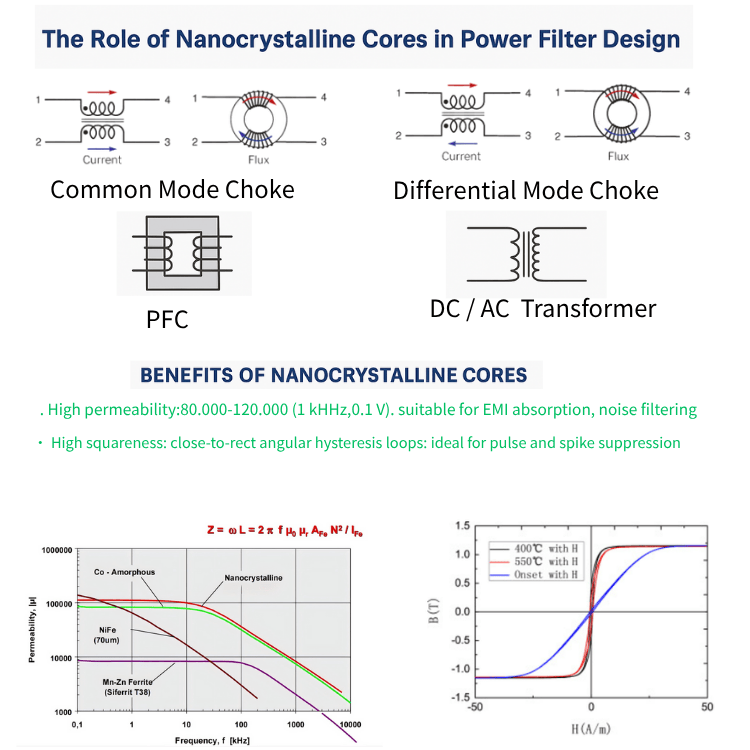

Compared with traditional ferrite cores, nanocrystalline cores offer significant benefits:

High Permeability: Enables higher inductance values with fewer turns, saving space and reducing cost.

Low Core Loss: Ensures excellent efficiency at high frequencies, making it suitable for EV power electronics.

Temperature Stability: Maintains consistent inductance over wide operating ranges (-40°C to +150°C).

Superior EMI Suppression: Effectively reduces noise, ensuring system-level stability in automotive circuits.

These properties make nanocrystalline cores ideal for EV power conversion systems, DC/DC converters, onboard chargers, and noise suppression circuits.

3. Key Specifications of the 191125 Nanocrystalline core

Size(mm): bear core: OD:19 ID:11 HT: 25 , Coated finished core: OD:19.5 ID:10.5 HT: 25.5

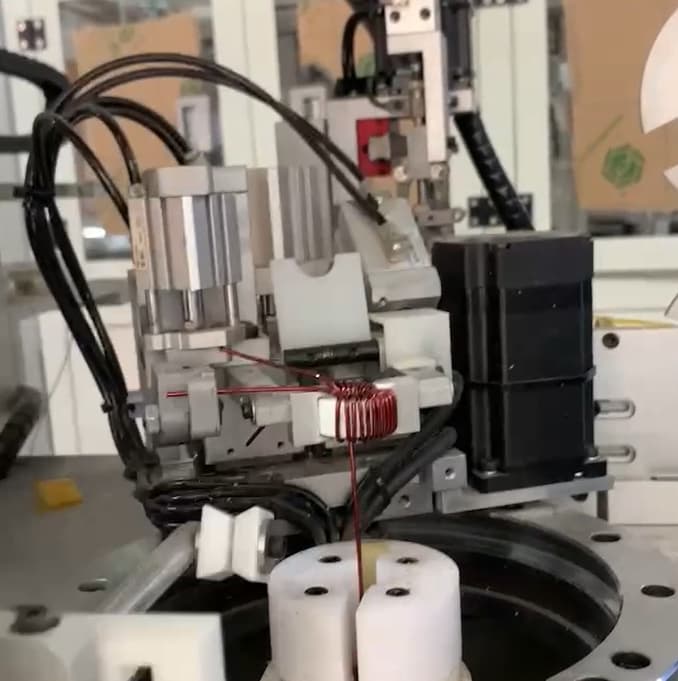

Structure: wound nanocrystalline core

Frequency Range: Optimized for 100KHz operation

Single Inductance Value: 52μH – 73μH

Application Focus: Automotive speed-limiting inductors, EV power management modules, onboard charging units

Such specifications prove the product’s suitability for automotive-grade performance, ensuring reliability in demanding EV systems.

4. Automotive Application Scenarios

a. Electric Vehicles (EVs)

The 191125 nanocrystalline inductor plays a critical role in EV motor control systems and battery management modules, where stable inductance ensures smooth current handling and improved energy efficiency.

b. Automotive Power Management Modules

In DC/DC converters and inverters, stable inductance minimizes ripple current, reduces heat generation, and improves overall system reliability.

c. Speed-Limiting Inductor Applications

As part of EMC compliance, speed-limiting inductors filter noise spikes and protect circuits against interference, ensuring safe vehicle operation.

d. Onboard Chargers & Charging Stations

In OBCs and fast-charging systems, inductors with low loss and high stability improve charging efficiency and extend battery life.

5. Why Choose the 191125 Nanocrystalline core for Automotive Inductor?

Automotive-Grade Reliability: Designed for high vibration, temperature, and humidity environments.

Stable Inductance Range: 52–73μH at 100KHz ensures predictable and efficient performance.

Long Lifespan: Nanocrystalline core materials reduce wear and degradation over time.

Energy Efficiency: Lower losses help optimize EV range and reduce heat dissipation.

Broad Applicability: Suitable for EVs, hybrid vehicles, onboard chargers, and smart automotive systems.

6. Market Trend and Industry Outlook

The global automotive inductor market is expanding rapidly, driven by the adoption of EVs, hybrid cars, and intelligent vehicle platforms. According to industry forecasts, demand for automotive-grade inductors will grow at double-digit rates over the next five years.

Nanocrystalline inductors are expected to dominate future applications due to their superior performance in high-frequency, high-power environments. The 191125 nanocrystalline core for inductor is well positioned as a reliable choice for next-generation EV power electronics.

The 191125 size nanocrystalline magnetic core for automotive inductor core combines stable inductance (52–73μH), low core loss, EMI suppression, and automotive-grade durability, making it the ideal solution for speed-limiting applications and other car electronics.

For more insights, contact JH Amorphous engineer team via sales@amorhpousoem.com.

As the world moves toward greener, smarter, and more energy-efficient transportation, choosing high-performance inductors is critical. The 191125 inductor not only enhances vehicle reliability but also contributes to safer driving and sustainable mobility.

Read More