Why Nanocrystalline Alloys Are the Core of Next-Generation Power Electronics

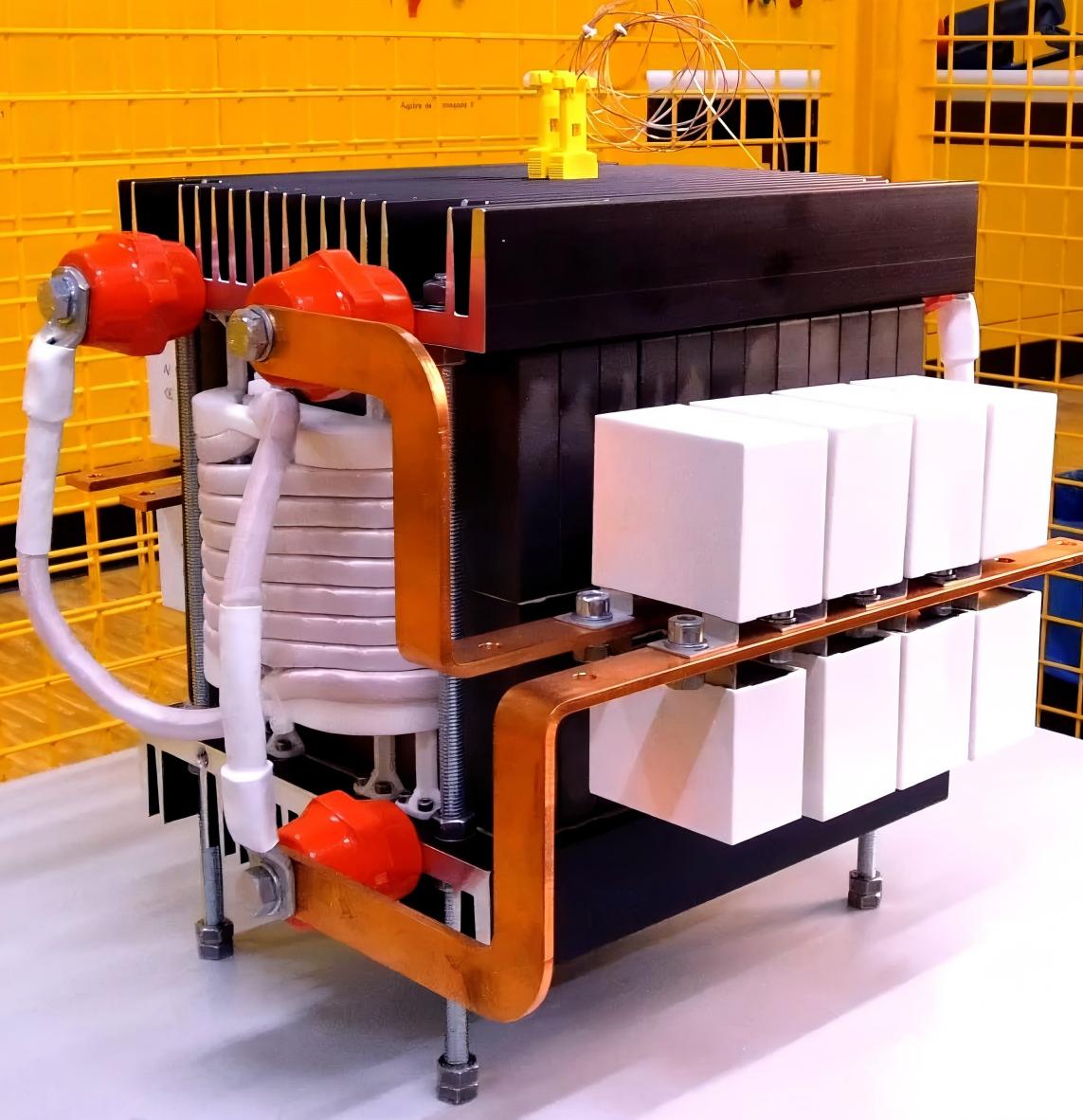

Nanocrystalline alloys deliver unmatched magnetic permeability, low core loss, and superior high-frequency stability—making them the ideal core material for solid-state transformers, EV chargers, and compact high-efficiency power systems.

Why This Material? — The Science Behind Nanocrystalline Alloys

Among all soft magnetic materials, very few can simultaneously achieve low loss, high permeability, and stable high-frequency performance.

Nanocrystalline alloys are the rare exception — a breakthrough material that bridges the gap between traditional silicon steel and amorphous alloys.

Structurally, a nanocrystalline alloy consists of ultrafine crystalline grains (10–20 nm) embedded within an amorphous matrix.

This hybrid structure combines the “no grain boundary, low eddy current” benefits of amorphous materials with the improved magnetic alignment of crystalline ones.

The result is a magnetic material that maintains high permeability, low loss, and excellent thermal and frequency stability — the perfect foundation for modern power electronics and solid-state transformers (SSTs).

1. High Magnetic Permeability — The Key to Compact Efficiency

Magnetic permeability defines how easily magnetic flux can pass through a material.

Nanocrystalline alloys offer permeability in the range of 10⁵–10⁶, far exceeding that of silicon steel (≈10³–10⁴) and amorphous alloys (≈10⁴–10⁵).

This enables transformers and inductors to shrink by 30–70% in volume and cut core weight by more than half, without sacrificing performance.

Even more critically, nanocrystalline alloys retain high permeability under kilohertz-level frequencies,while silicon steel and amorphous cores experience sharp declines.

That makes them the material of choice for high-frequency, high-efficiency SSTs, EV power modules, and data center converters.

2. Moderate Saturation Flux Density, Optimized for High-Frequency Stability

Unlike amorphous alloys with higher Bs (≈1.5T) but poor high-frequency stability,nanocrystalline alloys offer a moderate Bs of ≈1.2T, balanced by ultra-low loss and superior permeability at operating frequencies of several kHz to tens of kHz.

In high-power-density systems such as EV fast chargers or on-board DC/DC converters,where fast response and minimal heat buildup are essential,this balance allows higher efficiency, smaller size, and better thermal control.

Simply put — amorphous may saturate higher, but nanocrystalline runs cooler and smarter.

3. Low Core Loss and High-Frequency Efficiency — The Foundation of Power Electronics

The defining advantage of nanocrystalline alloys lies in their low total core loss across wide frequency ranges.

High resistivity (110–130 μΩ·cm) suppresses eddy current loss;

Tiny grain size (<20 nm) minimizes magnetic hysteresis and domain wall motion loss;

Uniform internal stress ensures stability even under high switching frequencies.

As a result, nanocrystalline cores deliver minimal power loss even at 10–50 kHz,making them the cornerstone for solid-state transformers and compact power converters that must operate efficiently under continuous high-frequency switching.

4. Thermal Stability and Reliability — Designed for Real-World Conditions

Nanocrystalline alloys maintain magnetic performance consistently across -40°C to 150°C,ensuring reliability in both freezing northern climates and tropical heat.

Their low loss and higher thermal conductivity reduce temperature rise within the magnetic core,simplifying cooling design and improving long-term system stability.

For next-generation SSTs and EV power modules that must operate continuously,this translates directly into greater reliability and longer service life.

5. From Innovation to Industrial Scale — The Maturity Advantage

Recent advances in ribbon casting, heat treatment, and coating technology have transformed nanocrystalline alloys from a lab innovation into a mass-produced industrial material.

With mature Fe-Si-B-Cu-Nb alloy systems and large-scale production lines,China now leads in global capacity and application development, bringing down costs and enhancing consistency.

Today, nanocrystalline ribbons are already used in solid-state transformers, EV fast chargers, UPS systems, and renewable power converters — validating their industrial readiness.

6. A Material for Its Time — The Energy Transition Catalyst

Every phase of the energy transition is defined by a breakthrough material:

The grid era belonged to silicon steel.

The energy-saving transformer era belonged to amorphous alloys.

The high-frequency, power-electronics era belongs to nanocrystalline alloys.

With global surges in EVs, AI data centers, renewable energy, and high-efficiency charging,nanocrystalline materials are no longer an upgrade — they’re a necessity.

Nanocrystalline alloys are not just “better materials.”

They are the enabling foundation of tomorrow’s power electronics ecosystem.

Refer to our blog