In the competitive electronics industry, passive component manufacturers are constantly seeking ways to improve performance, reliability, and efficiency. One recent case demonstrates how the adoption of a 20×15×10mm nanocrystalline core not only met technical requirements but also delivered measurable business results.

A leading passive component manufacturer faced challenges with core efficiency and stability. Their existing solutions could not meet the growing demand for:

Higher inductance in a compact size

Lower energy losses

Improved long-term reliability

They needed a material that could deliver superior performance while maintaining cost-effectiveness.

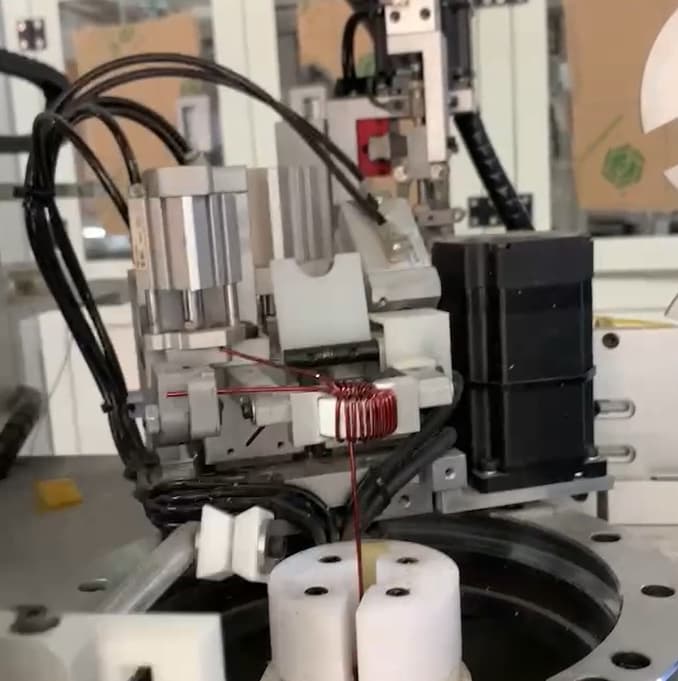

The customer decided to test a 20×15×10mm nanocrystalline core. This core, wound with high-quality copper wire, provided:

High magnetic permeability for better inductance

Low core losses at operating frequencies

Compact size with strong performance

The design change required minimal process adjustments, making integration smooth and efficient.

The results were immediate and impactful:

✅ Enhanced product performance — Stable inductance and lower loss improved the customer’s final components.

✅ High customer satisfaction — End-users noticed the reliability, leading to positive feedback.

✅ Repeat orders — The customer reported continuous reorders after the switch.

✅ Profit growth — With stronger product competitiveness, profits increased by 5%.

The customer shared that the nanocrystalline core exceeded expectations:

“By integrating the nanocrystalline core, our components gained a real edge in the market. Our clients are satisfied, and we’ve seen steady repeat business.”

This case illustrates the strategic value of nanocrystalline technology:

🌟 Higher efficiency compared to traditional ferrite or FeSiAl cores

🌟 Compact size without compromising performance

🌟 Proven reliability and durability

🌟 Direct business benefits — from customer trust to profit growth

The success of this 20×15×10mm nanocrystalline core application highlights the power of advanced materials in driving both technical and commercial results. For passive component manufacturers, adopting nanocrystalline cores can mean not just better performance, but also stronger customer loyalty and improved profitability.

👉 If you are looking for ways to enhance efficiency and gain a competitive advantage, nanocrystalline cores are a proven solution.