Nanocrystalline Cores for EMI Suppression in EV Heater Systems – Design Guid

In electric vehicle (EV) thermal management systems, the EV heater is a key high-voltage component. However, its switching operation and high power levels generate significant electromagnetic interference (EMI), which can impact overall electromagnetic compatibility (EMC) compliance.

Among available magnetic materials, iron-based nanocrystalline cores (such as FINEMET®, 1K107B) are increasingly popular for common-mode chokes (CMCs), current transformers, and localized magnetic shielding. Their high permeability, low loss, and thermal stability make them especially effective in specific EMI suppression scenarios.

Installed close to noise sources or chassis entry points; affects only common-mode currents.

Wrap tape shields around noisy components; ground appropriately to reduce coupling.

| Material | μᵢ Range | Bₛₐₜ (T) | Frequency Strength | DC Bias Tolerance | Typical Uses |

|---|---|---|---|---|---|

| Nanocrystalline | 10⁴–10⁵ | ~1.2 | 10 kHz–10 MHz | Fair | CMC, shielding, CT |

| MnZn Ferrite | 10²–10³ | ~0.45 | 100 kHz–5 MHz | Fair | CMC, gapped energy storage |

| NiZn Ferrite | 10–10² | ~0.35 | 5–100+ MHz | Fair | High-frequency suppression |

| Powder Cores | 10–100 | 0.8–1.5 | Stable under DC bias | Strong | Differential-mode inductors |

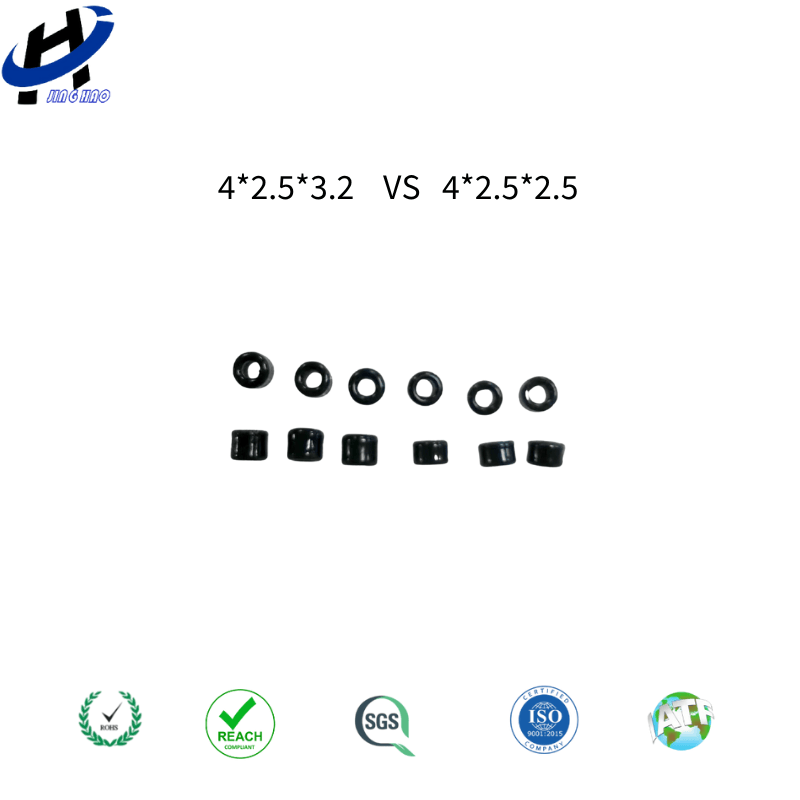

For more details about nanocrystalline core info., click https://www.amorphousoem.com/product/fe-based-1k107-42525mm-nanocrystalline-bead-for-spike-suppression