With electric vehicles, solar inverters, and 5G power systems growing fast, one thing is clear: power filters are no longer optional. They're mission-critical.

EMI (electromagnetic interference) is a major headache in modern electronics. If you can’t control noise, you risk failing CE, FCC, or CISPR compliance — and losing the project.

So how is power filter design evolving? And why are more engineers switching to nanocrystalline magnetic cores?

Let’s break it down.

The global EMI filter market is expected to hit $1.5 billion by 2030

Nanocrystalline core demand is growing fast — from $1.3B in 2023 to $2.8B by 2030

EV charging stations, solar power, telecom power modules — all need compact, high-performance filters

Designers must meet stricter EMC rules while shrinking size and boosting efficiency

✅ Higher Frequencies

Modern systems use SiC and GaN chips that switch at hundreds of kHz — even MHz. Ferrites can't keep up.

✅ Smaller Footprint

Designers want smaller filters, especially for EVs and telecom. You need materials that pack more power in less space.

✅ Tougher EMC Requirements

Filters now need 60dB+ noise reduction across 150kHz to 30MHz and beyond.

✅ Passing Certification Is Harder

Failing EMC tests means delay, redesign, or lost business.

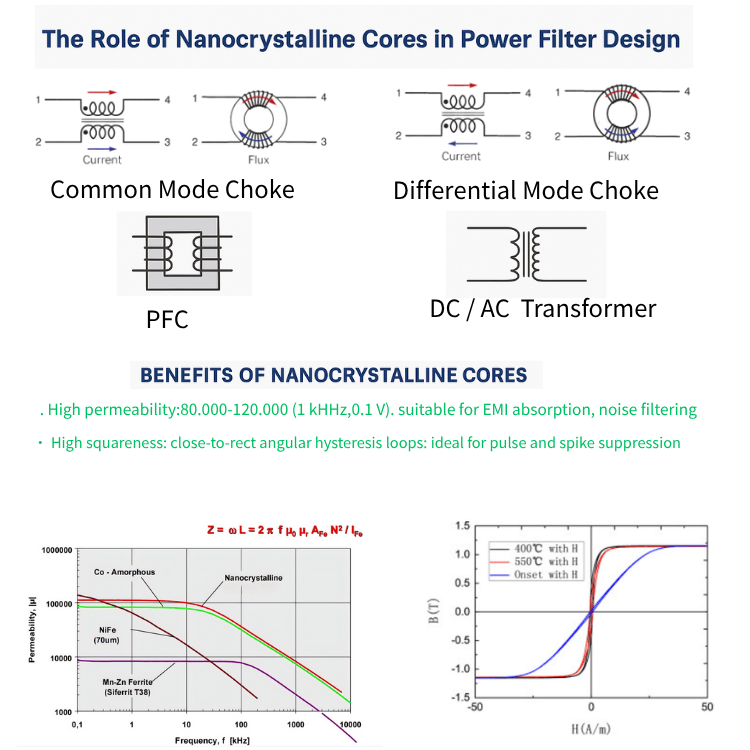

| Feature | Why It Matters |

|---|---|

| Ultra-high permeability (80k–120k @ 1kHz, 0.1V) | Absorbs EMI better, allows compact designs |

| High squareness ratio (Br/Bs ≈ 1) | Excellent spike and surge suppression |

| Low core loss at high frequencies | Runs cooler, saves energy |

| Stable under heat | Reliable even in harsh environments |

| Helps meet EMC standards | Easier CE/FCC/CISPR compliance |

🔹 Common Mode Chokes

Placed on AC input to block common-mode noise

→ Use toroidal nanocrystalline cores

🔹 Differential Mode Filters

Placed after rectifiers or near outputs to block high-frequency switching noise

→ Use gapped toroidal or cut cores

🔹 PFC Inductors

Placed in front of power factor correction stages to handle high current

→ Use nanocrystalline C-cores or E-cores

🔹 Output Filters & Transformers

Placed near the load or in DC/DC converters

→ Use custom-wound nanocrystalline cores

✅ Reduce the number of filter stages

✅ Shrink your filter size and weight

✅ Improve system energy efficiency

✅ Lower EMI and meet compliance faster

✅ Design for tomorrow’s high-frequency needs — today

We are an experienced OEM/ODM manufacturer of nanocrystalline and amorphous magnetic cores, serving customers worldwide in EV, inverter, power supply, and telecom industries.

🌐 Website: www.amorphousoem.com

📩 Email: julia@amorphousoem.com

📱 WhatsApp: +86 13686646827

💡 Contact us for:

✅ Free sample kits

✅ Filter design tips

✅ Custom core manufacturing

Let’s engineer better filters — together.