Jun 13, 2025

With the popularity of electric vehicles, the demand for high-efficiency power electronic components in the electric vehicle industry continues to grow. As an important supporting facility for electric vehicles, the performance and stability of charging piles are increasingly concerned. In the internal structure of charging piles, nanocrystalline magnetic cores are an indispensable component, which plays a vital role in improving the efficiency and safety of charging piles.

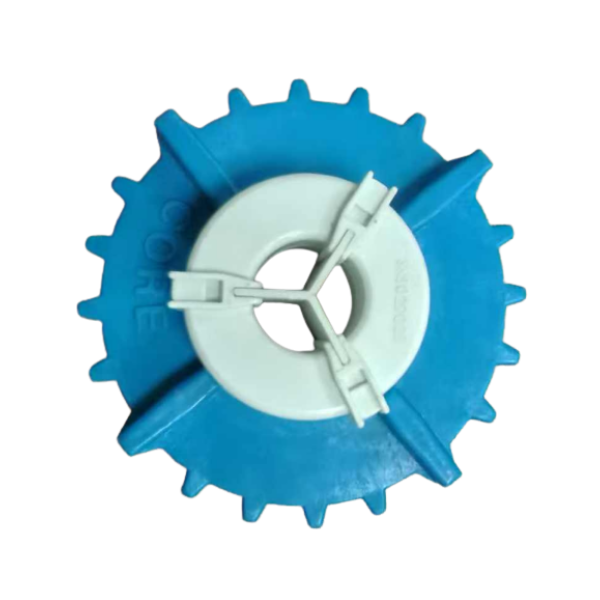

Nanocrystalline magnetic core is a material composed of ultrafine particles, with a grain size usually ranging from tens to hundreds of nanometers. The core component is iron oxide containing iron elements, and the surface is covered with a non-ferromagnetic film layer. This structure achieves better electromagnetic properties by changing the magnetic properties of traditional magnetic cores.

Unique advantages of nanocrystalline cores

Compared with traditional silicon steel sheets or ferrite materials, nanocrystalline cores have the following significant features:

Extremely high magnetic permeability (up to 100,000 µ)

Extremely low loss at high frequencies

Excellent thermal stability

Smaller size but higher energy density

These characteristics allow engineers to design smaller and more efficient magnetic devices, especially for scenarios such as on-board chargers and DC-DC converters.

In the process of fast charging of electric vehicles (EVs), power converters (such as high-frequency transformers, filters, and inductors) are core components, and their efficiency directly affects the charging speed and energy utilization. Traditional silicon steel or ferrite core materials are prone to hysteresis loss and eddy current loss when operating at high frequency and high power, while nanocrystalline cores have obvious advantages in this scenario due to their extremely high magnetic permeability (usually more than 10 times that of ferrite) and low loss characteristics.

In addition, nanocrystalline materials also have good resistance to DC bias magnetism, which effectively improves the stability of transformers and inductors during high-frequency repeated charging and discharging, reduces EMI interference, and improves the overall reliability and life of the charging system.

For example,a large European charging pile manufacturer replaced ferrite materials with nanocrystalline toroidal cores in a 22 kW fast charging module, and the overall energy efficiency of the system increased from 94.5% to 97.2%. The use of nanocrystalline toroidal cores reduces the overall size and cost; the heat sink is reduced to save space; the heat is reduced and the safety performance is improved.

Taking a charging station that works 10 hours a day as an example, the annual power saving can reach 200 kWh, with obvious long-term benefits.

The energy-saving advantages of nanocrystalline cores in electric vehicle charging piles fully demonstrate their great potential in improving energy efficiency. However, their applications go far beyond charging equipment. In a wider range of power electronic systems, especially in scenarios with high requirements for high-frequency operation, miniaturized structure and thermal stability, nanocrystalline cores are being increasingly adopted and showing excellent performance.

Nanocrystalline cores in inverters and power electronics

In high-power inverters such as electric buses or industrial motor drives, custom nanocrystalline cores can effectively suppress EMI (electromagnetic interference) and withstand high-frequency ripple currents. With a saturation flux density of up to 1.2T, they still provide strong performance in a compact design.

For example, a 100 kW electric bus inverter system, after replacing the raw materials from amorphous cores with nanocrystalline magnetic components, the overall weight of the system was reduced by 8%, the thermal stability was improved by 15%, and the component life was significantly extended.

Due to its excellent high-frequency performance and low energy consumption characteristics, nanocrystalline core materials are now widely used in:

Electric vehicle on-board chargers

Photovoltaic inverters

Transformers for smart grids

High-frequency switching power supplies

Compared with traditional amorphous cores, nanocrystalline materials have lower coercivity and higher saturation flux density, making them the first choice for the new generation of power electronic systems.

As electric vehicles and new energy power systems continue to develop, nanocrystalline cores play an increasingly critical role in improving efficiency, optimizing thermal management, and achieving high-frequency compact designs. If you are developing power components or EV charging systems, please learn about our customized nanocrystalline cores, high-frequency magnetic materials, and soft magnetic material component solutions.

As a full-service, one-stop amorphous core manufacturer, we provide comprehensive servces including winding, annealing, coating, and custom assembly. Contact us now!

Read More