Tips of how to choose Fe-based Amorphous or Nanocrystalline Magnetic Cores

By Senior Applications Engineer, Dongguan JH Amorphous Co., Ltd.

Visit: www.amorphousoem.com

Magnetic cores are critical in suppressing EMI, increasing efficiency, and managing energy conversion in power electronics. At Dongguan JH Amorphous, we manufacture both Fe-based Amorphous and Fe-based Nanocrystalline cores. While they appear similar in structure, their magnetic properties, temperature behavior, and application targets differ significantly.

This article provides a side-by-side technical overview to help engineers select the most suitable core material based on design priorities like saturation flux, operating temperature, resistivity, and mechanical strength.

Relationship between Amorphous and Nanocrystalline Alloy

Amorphous Metals have a unique non-crystalline structure and possess excellent physical and magnetic properties that combine strength and hardness with flexibility and toughness.

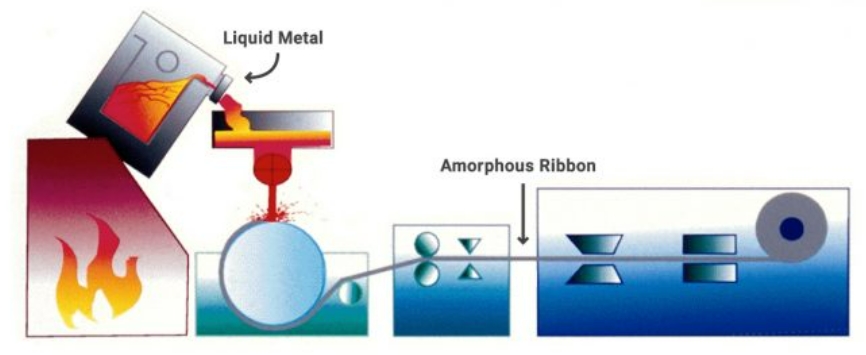

The key to amorphous proprietary manufacturing process is the rapid-solidification of molten alloy at a rate of approximately one million degrees Celsius per second, forming a disordered atomic structure without long-range crystalline order.

Nanocrystalline cores are developed from amorphous materials by applying controlled annealing, which causes the formation of nanometer-sized grains (10–30 nm) within the amorphous matrix.

Nanocrystalline materials originate from amorphous materials and are formed through heat treatment.

Difference

Part 1: Fe-Based Amorphous Cores

Key Characteristics

|

Property |

Fe-Based Amorphous |

|

Saturation Flux Density (Bs) |

1.56 T |

|

Electrical Resistivity |

130 μΩ·cm |

|

Crystallization Temperature |

508 °C |

|

Curie Temperature |

400 °C |

|

Vicker’s Hardness |

860 Hv |

|

Density |

7.18 g/cm³ |

|

Initial Permeability(μi) |

5,000 |

|

Coercivity Hc (A/m) |

2.4 |

|

Working Temperature |

-20 ~ 150°C |

Advantages

High Saturation Flux: Ideal for applications that need high peak flux without early saturation.

Good Electrical Resistivity: Reduces eddy current loss in mid-frequency range.

Cost-effective: Generally more economical than nanocrystalline alloys.

Stable for ≤100 kHz Applications: Excellent for low-frequency and mid-frequency common-mode chokes and transformers.

Common Applications:

AC line filters (50/60 Hz)

Output chokes in inverters

Power Factor Correction (PFC) input filters

General EMI suppression in household appliances

Example Case:

A 10 A common-mode filter in a household inverter passed EMC Class

B after replacing ferrite with a JH amorphous toroid (35×20×10 mm). Losses reduced by 20% with minimal temperature rise.

Part 2: Fe-Based Nanocrystalline Cores

A nanocrystalline alloy of a standard iron-boron-silicon alloy, with addition of smaller amounts of copper and niobium, called NANOPERM (Fe–Zr–Nb–Cu–B) alloys.

It is available under names like e.g. Nanoperm(Fe73.5 Cu1 Nb3 Si15.5 B7) registered by Magnetec, Vitroperm registered by VAC, Hitperm and Finemet registered by Hitachi Metals, Ltd., and Metglas is a registered by Metglas®, Inc.

|

Property |

Fe-Based Nanocrystalline |

|

Saturation Flux Density (Bs) |

1.2 T |

|

Electrical Resistivity |

115 μΩ·cm |

|

Crystallization Temperature |

510 °C |

|

Curie Temperature |

570 °C (↑ very high) |

|

Vicker’s Hardness |

960 Hv |

|

Density |

7.2 g/cm³ |

|

Initial Permeability(μi) |

80,000 |

|

Coercivity Hc (A/m) |

1.2 |

|

Working Temperature |

-40 ~ 140°C |

Advantages

Extremely High Initial Permeability (µi): Up to 80,00~120,000, significantly better than amorphous or ferrite.

Lower Core Loss: Particularly effective in 20 kHz–1 MHz range.

High Thermal Stability: Suitable for continuous operation at elevated temperatures (up to 140 °C).

Ideal for EMI Suppression: Excellent for fast-switching SiC/GaN circuits where broadband noise filtering is critical.

Common Applications

High-frequency EMI chokes (20 kHz–100 MHz)

EV on-board charger filters

Solar inverter output stages

SMPS and server power supplies

Differential-mode and common-mode chokes in automotive/rail/aerospace/marine

Example Case:

In a 20 kW EV charger filter, the replacement of ferrite with a nanocrystalline JH-60×35×15 core resulted in a 30% loss reduction, 8 dB EMI improvement, and a 25 °C lower core temperature under full load.

Material Selection Guide

|

Application Type |

Recommended Core |

Notes |

|

Low-frequency EMI Filter (≤100 kHz) |

Fe-based Amorphous |

Cost-effective, stable, suitable for Class B filters |

|

High-frequency EMI Filter (100 kHz+) |

Fe-based Nanocrystalline |

Superior suppression for fast-switching applications |

|

Harsh Thermal Environments |

Nanocrystalline |

Higher Curie temperature and thermal endurance |

|

High Saturation Flux Requirements |

Amorphous |

Bs = 1.56 T for larger flux window |

When choosing between amorphous and nanocrystalline magnetic cores, it's essential to match your design frequency, thermal limits, and EMI suppression goals with the right material.

Use amorphous when budget, space, and low-frequency performance are key.

Choose nanocrystalline when performance, high-frequency stability, and thermal resilience are critical.

At Dongguan JH Amorphous, we offer full OEM customization, quick sample delivery, and application engineering support.

Learn more: www.amorphousoem.com