How to Improve Cased Nanocrystalline Core Performance: The Game-Changing Impact of Varnish Curing Before Casing

As a professional OEM/ODM manufacturer and global exporter of nanocrystalline and amorphous magnetic cores, we’ve faced — and solved — one of the most frustrating problems in magnetic component manufacturing: performance degradation of cased nanocrystalline cores after copper winding.

Despite our best efforts with process control and material optimization, the issue remained. Until we discovered one simple yet powerful step that changed everything: varnish curing of the core before casing.

In this article, we’ll walk you through the core problem, why conventional fixes don’t work, and how pre-casing varnish curing is a proven solution to improve cased nanocrystalline core performance in real-world production.

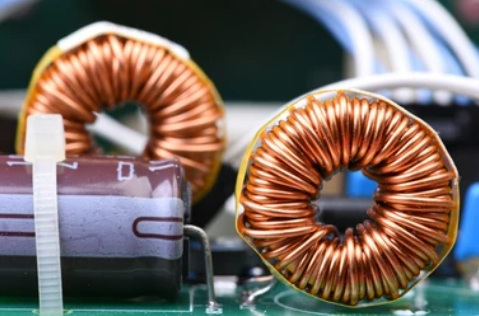

Cased nanocrystalline cores — usually toroidal or rectangular cores sealed with plastic, epoxy, or metal shells — are widely used in:

High-frequency transformers

Common mode chokes

EMI filters

Inverters and power supplies

Before being integrated into magnetic components, these cores are typically cased for mechanical strength, electrical insulation, and ease of handling. However, once copper winding is applied to these cased cores, we consistently observed a decline in performance, including:

Lower initial permeability

Higher core loss

Reduced stability under temperature variation

Poorer high-frequency behavior

These issues directly affect the quality and efficiency of the final device.

We tried:

Adjusting winding tension

Controlling ambient humidity and temperature

Improving casing procedures

Post-winding annealing

None of these consistently prevented the performance drop in cased cores after winding.

We experimented with:

Different casing materials

Various adhesives and bonding resins

Modified insulation layers

Again, results were unstable. The degradation continued.

Nanocrystalline ribbon is highly sensitive to mechanical stress and surface tension. During the winding process, pressure from the copper wire and friction from the casing interface can disturb the internal magnetic domains of the ribbon.

In cased products, this stress is harder to relieve because the core is confined within a rigid structure. Once distorted, the magnetic domains no longer function optimally — permeability drops, core loss increases, and overall stability suffers.

After multiple tests, we found a breakthrough: spraying insulating varnish on the bare nanocrystalline core and curing it before applying the casing and winding.

This varnish — specifically, a solvent-free polymer-based varnish such as V852-3 — forms a thin, flexible, nanograde insulating layer on the surface of the core. Once cured, it acts as a buffer between the magnetic material and mechanical stress.

Core Surface Cleaning: Dust, oil, and oxidation are removed.

Varnish Spraying: The varnish is evenly sprayed over the entire surface.

Curing: The core is baked at 80–120°C for 30–60 minutes, depending on size.

Casing: The cured core is then inserted into the casing.

Winding: Copper coils are applied as usual.

Reduces Stress Sensitivity: The cured layer absorbs winding pressure and mechanical stress from the casing.

Preserves Magnetic Domains: Magnetic alignment remains stable under force and heat.

Improves Thermal Cycling Stability: Coating remains intact even after repeated temperature changes.

Enhances Surface Uniformity: Coating smooths minor imperfections, improving magnetic consistency.

After adopting varnish curing in our production line, we observed the following:

| Test Parameter | Without Varnish | With Pre-Casing Varnish |

|---|---|---|

| Initial Permeability (μi) | Drops 15–25% after winding | Stays within ±5% range |

| Core Loss @20kHz, 0.1T | Increases by 30% | Reduced by 20–30% |

| High-Frequency Stability | Inconsistent | Stable across samples |

| Production Rejection Rate | ~8–10% | <2% |

We also received positive feedback from export customers in Europe, South Korea, and the US, especially those working in automotive power supplies, photovoltaic inverters, and EV charging systems.

| Method | Effectiveness | Comments |

|---|---|---|

| Process tuning | ★☆☆☆☆ | Temporary benefit, not scalable |

| Casing material change | ★★☆☆☆ | Costly and still stress-sensitive |

| Annealing post-winding | ★☆☆☆☆ | Risky in cased products |

| Varnish curing before casing | ★★★★★ | Simple, stable, and proven effective |

High-frequency transformers (20kHz–100MHz)

Common-mode chokes for EV charging

EMI suppression for power electronics

Photovoltaic inverters and wind converters

UPS systems and power storage devices

DC-DC converters in automotive and rail

With over 10 years of experience in nanocrystalline and amorphous magnetic core production, we provide:

Customized OEM/ODM services

Cased and uncased cores in toroidal, cut, and block shapes

High-frequency, high-efficiency materials

Mass production with stable quality control

Global export logistics and multilingual support

We do not manufacture varnish, but we successfully integrate varnish curing into our own core production lines to deliver the best performance for our customers.

If you're tired of post-winding performance issues in cased cores, consider switching to a better solution.

Let us help you:

🧪 Request free samples

🛠 Get custom nanocrystalline core / amorphous core solutions

📦 Start stable OEM/ODM partnerships

🌍 Deliver globally with technical support

🌐 Website: www.amorphousoem.com

📱 WhatsApp: +86 13686646827

📩 Email: julia@amorphousoem.com

🕘 Working Hours: Mon–Sat, 8:00–18:00 (China Time)