Jul 15, 2025

Magnetic cores are vital components in electronics, essential for efficient energy conversion in transformers, inductors, and chokes. The right core material significantly impacts a device's performance, efficiency, size, and cost. This article compares two key materials: traditional ferrite cores and advanced nanocrystalline cores.

1. What Are Ferrite and Nanocrystalline Cores?

Understanding their basic structure is key to their properties.

Ferrite Cores: The Established Workhorse

Ferrite cores are dense ceramic structures made primarily from iron oxide (Fe2O3) mixed with other metal oxides like manganese, zinc, nickel, or magnesium. These mixtures are shaped and fired at high temperatures (around 1300°C). Their high electrical resistivity minimizes eddy current losses, making them ideal for low-frequency applications. Ferrites offer design flexibility and can be molded into various shapes, including U-cores low power allpications. MnZn ferrites are typically used below 5 MHz, while NiZn ferrites suit 0.01MHz up to 20MHz.

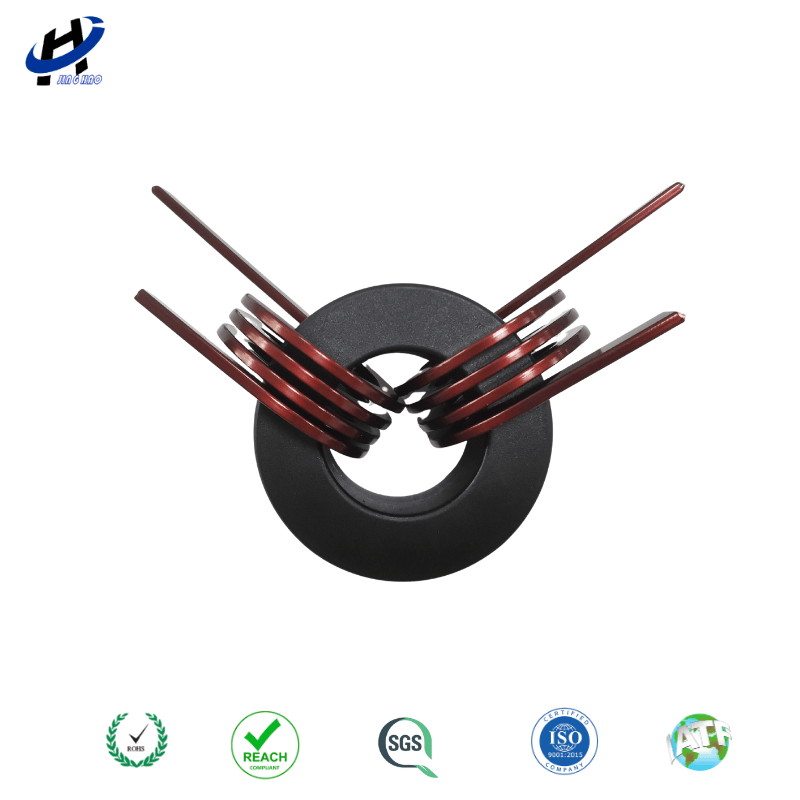

Nanocrystalline Cores: The High-Performance Innovator

Nanocrystalline cores are advanced soft magnetic materials with exceptionally small grain sizes, typically 10 to 20 nanometers.Their metallic alloy composition is mainly iron (Fe) with additions of silicon (Si), boron (B), niobium (Nb), and copper (Cu).They are manufactured by rapidly solidifying molten metal into an amorphous ribbon, then precisely heat-treating it to induce nano-crystallization.This nanoscale structure results in remarkably low core loss, low magnetostriction, high saturation induction, and very high initial permeability,over 80Kμm at 10KHz and over 20Kμm at 100KHz.They also exhibit excellent thermal stability from -40 to 120 degree celsius.

2. Ferrite vs. Nanocrystalline: A Performance Showdown

Nanocrystalline materials generally outperform ferrite cores in critical magnetic properties, though ferrite retains specific advantages.

Advantage of Nanocrystalline Core

Nanocrystalline cores offer significant performance benefits:

Permeability: Nanocrystalline materials have significantly higher permeability, often ten times that of ferrite cores.This allows for smaller, more efficient components with fewer turns.

Saturation Flux Density (Bs): Nanocrystalline cores boast a much higher saturation flux density (1.2 T to 1.32 T) compared to ferrite cores (around 0.3 T to 0.49 T for MnZn ferrite).This means they can handle stronger magnetic fields without saturating, enabling more powerful designs.

Core Loss: A major advantage of nanocrystalline core is their significantly lower core losses across a wide frequency range. This leads to enhanced energy efficiency, less heat generation, and simpler thermal management.

Frequency Response: Nanocrystalline cores offer a broadband frequency range and maintain properties at very high frequencies, such as 20MHz in transformers, due to vanishingly low magnetostriction.

Thermal Stability: Nanocrystalline cores show superior thermal stability, with stable core loss from -40°C to 140°C and a high Curie temperature around 570°C. Ferrite core loss can vary more with temperature.

Size & Weight: The superior magnetic properties of nanocrystalline cores enable smaller and lighter components, leading to higher power density (e.g., up to 12 W/cm³ compared to 6 W/cm³ for ferrite transformers).This is crucial for miniaturization.

Where Ferrite Remains a Strong Choice & Considerations

Despite nanocrystalline's superior performance, ferrite cores remain relevant:

Cost-Effectiveness: Ferrite cores are generally more economical and easier to produce.While nanocrystalline cores offer higher performance, they typically have a higher upfront cost.

Specific Application Suitability: For simpler EMI noise scenarios with low energy or single frequencies, inexpensive ferrite cores are often sufficient and more cost-effective.

High Permeability Challenge: The extremely high permeability of nanocrystalline cores can sometimes lead to saturation issues in specific toroidal core designs, where a ferrite material with low permeability might be more effective.

Table 1: Ferrite vs. Nanocrystalline Core Comparison

Property

Ferrite Core

Nanocrystalline Core

Composition

Ceramic (Iron Oxide + Mn/Zn/Ni/Mg oxides)

Metallic Alloy (Fe, Si, B, Nb, Cu)

Typical Grain Size

Micrometers

Nanometer range (10-20 nm)

Permeability (µ)

Lower (e.g., 5000+ for MnZn)

Very High (e.g., 20,000 – 200,000µ)

Saturation Flux Density (Bs)

Lower (e.g., 0.3-0.49 T)

Higher (e.g., 1.2-1.25 T)

Core Loss (relative)

Higher

Very Low (e.g., 1000x reduction vs SiFe)

Frequency Range

Up to 20KHz (MnZn <5MHz)

Broadband (up to 20MHz for

Thermal Stability

Less stable (loss varies with temperature)

Excellent (stable -40°C to 140°C, high Curie ~570°C)

Typical Cost (relative)

Lower

Higher

Size Implication

Larger components

Smaller/Lighter components

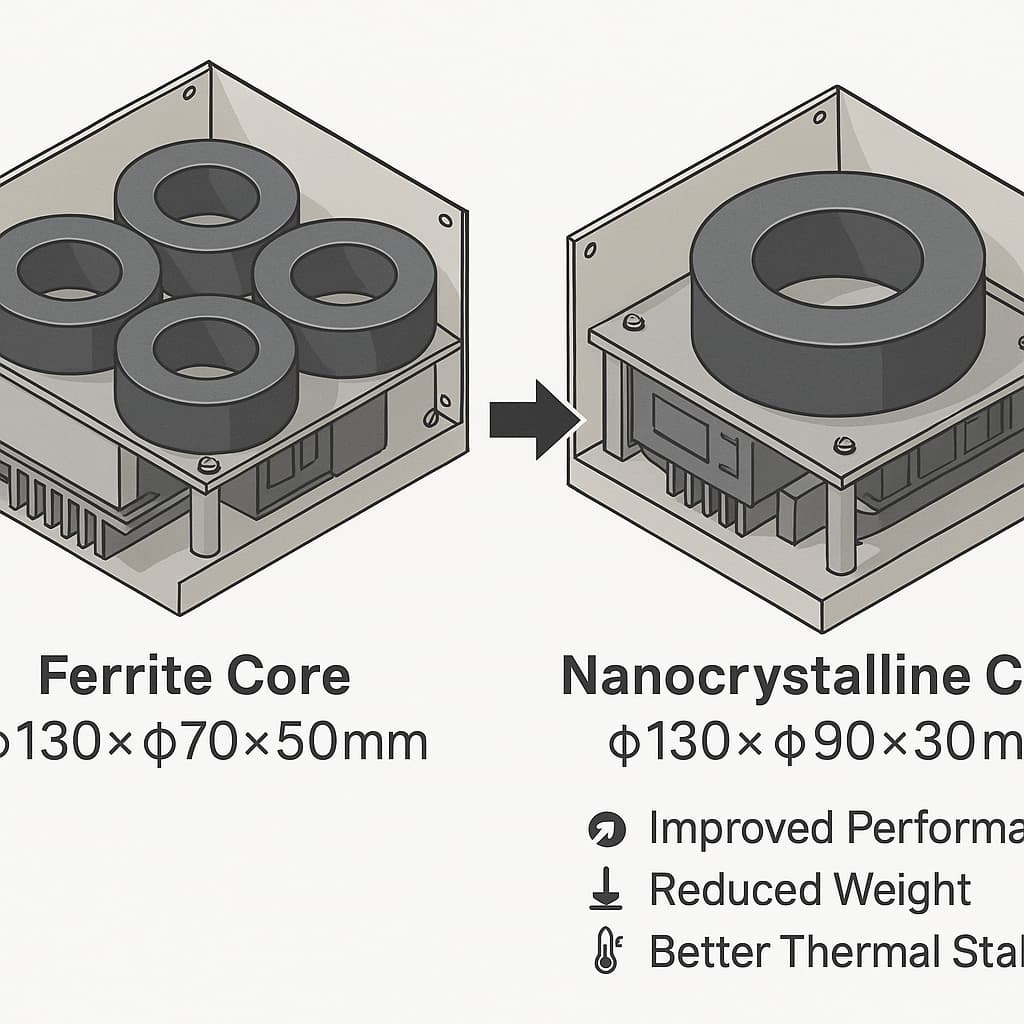

In a military-grade three-phase switching power supply project, the customer originally used four high-performance ferrite magnetic cores (φ130 × φ70 × 50 mm). These were successfully replaced by a single conventional nanocrystalline core (φ130 × φ90 × 30 mm). The change not only reduced the number of components but also enhanced overall system performance and thermal reliability.

Key highlights of this case include:

- Structural optimization: 4× Ferrite cores → 1× Nanocrystalline core

- Size & Weight: Despite larger individual size, only one nanocrystalline core was needed

- Performance: Improved efficiency and temperature control at 100 A operating current

- Design Margin: The system maintained performance redundancy, enhancing long-term reliability

3. Applications: Where Each Core Excels

The distinct properties of ferrite core and nanocrystalline core make them suitable for different applications.

Ferrite Core Applications

Ferrite cores are widely used due to their reliability and cost-effectiveness:

General low-Frequency Applications: low-frequency transformers, wideband transformers, adjustable inductors.

Power Applications: Power transformers , converter/inverter transformers, voltage converters, output chokes, and Switched-Mode Power Supplies (SMPS).

Noise and Interference Suppression: Noise filters and EMI line filters, especially for simpler EMI scenarios.

Sensing and Control: Measuring and instrumentation transformers, electric fencing, motor speed control, loading sensing, earth leakage sensing, and LED drivers.

Nanocrystalline Core Applications

Nanocrystalline cores are used in cutting-edge, high-performance applications where efficiency and miniaturization are critical:

Advanced Power Electronics: High-performance power transformers, inductors, and chokes for compact, lightweight designs, ideal for high current output inverters.

Electric Vehicles (EVs): Crucial in EV chargers, motor drives, and battery management systems, minimizing energy losses for faster charging and extended range.

Renewable Energy Systems: Improved performance at high frequencies for efficient power conversion.

Current and Magnetic Sensors: High sensitivity and accuracy due to excellent magnetic properties.

Complex EMI Suppression: Excel in EMI suppression and common mode chokes for high-energy or multi-frequency noise due to high impedance and wide effective frequency band.

Telecommunications: Contribute to faster data transfer and more compact, reliable equipment by minimizing signal distortion and handling high power densities.

Other High-Performance Fields: UPS systems , medical imaging (MRI) , and aerospace.

4. Powering Innovation with the Right Core

Choosing the optimal magnetic core is a strategic decision impacting design success and competitiveness.

Dongguan JH Amorphous is committed to tailored solutions, from standard offerings to custom configurations. Our engineering support is available at every stage to ensure optimal results. Partner with us to achieve your design goals and ensure the reliability of your electronic systems.

Contact our experts today to discuss your project requirements and explore our range of high-quality magnetic core solutions.

Read More