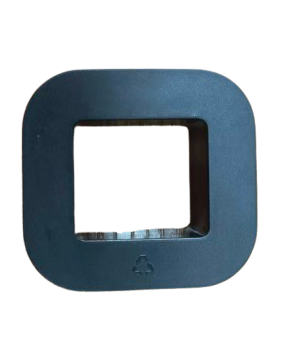

JHNO50.5*54*18 Nanocrystalline Common Mode Choke Core for EV On-Board Chargers (OBC)

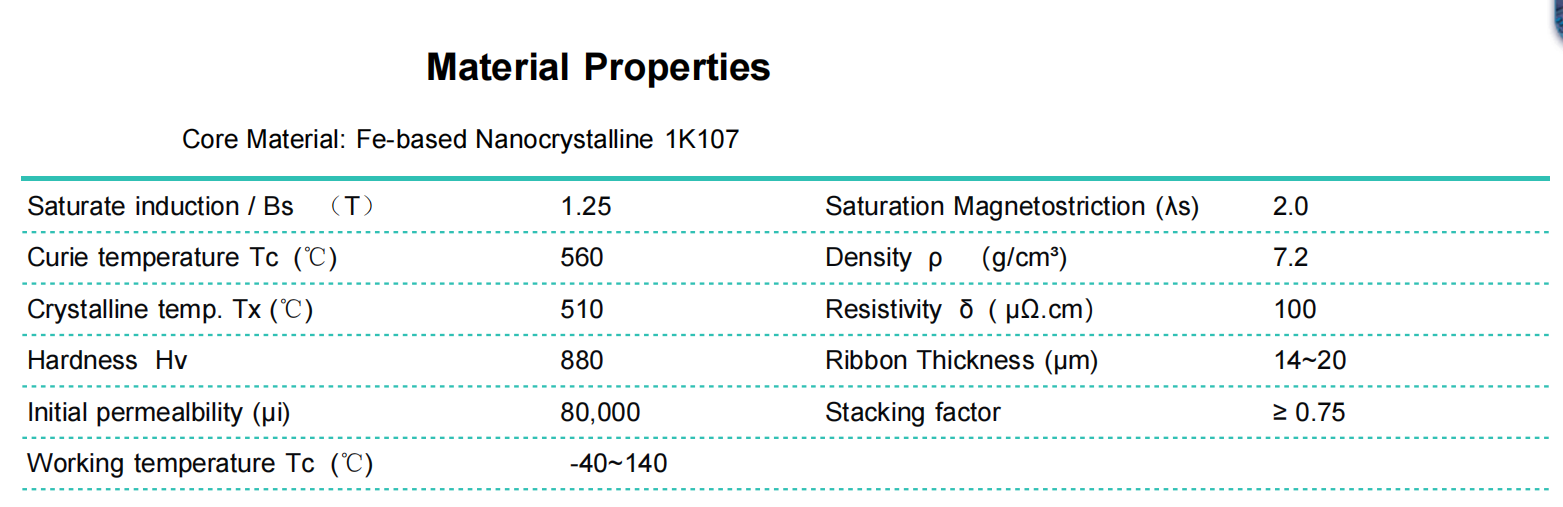

Engineered for automotive EV/HEV applications, this high-performance Nanocrystalline core delivers superior EMI suppression for On-Board Chargers (OBC) and DC/DC converters. Featuring a high saturation flux density (Bs=1.25T) and extreme thermal stability, it allows engineers to downsize magnetic components while maintaining high impedance across a wide frequency range (-40°C to +140°C).

Item No :

JHNO 55*31*18Order(MOQ) :

Flexible, Adjust based on customer requirementsCertification :

IATF16949, ISO9001, RoHSTrademark :

JHOrigin :

ChinaHS Code :

8504909000 ( Cores) or 8504500000 (Inductors)Production Capacity :

2,000,000 / Month

The Nanocrystalline Core (50.5*54.0*18.0) is a high-performance magnetic component designed to solve critical thermal and EMI challenges in modern power electronics. Unlike traditional Ferrite cores, this iron-based nanocrystalline material maintains stable magnetic properties even under high thermal stress, boasting a Curie temperature of 570°C and a saturation flux density of 1.25 T.

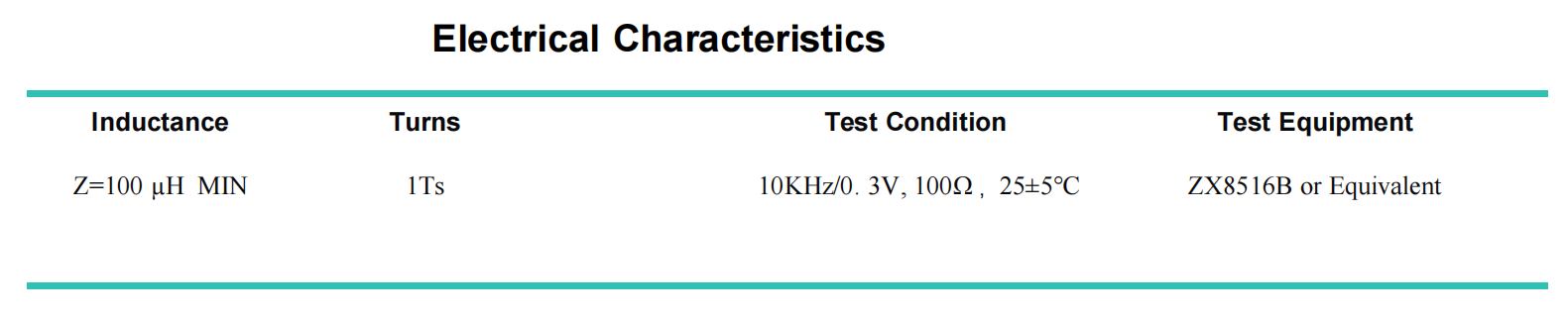

With a generous Inner Diameter (ID = 31.3 mm) and a high inductance factor (AL ≥ 100.0 μH @ 1kHz), this core is optimized for high-current windings, making it the ideal solution for common mode chokes where space is limited but high impedance is required.

Key Features & Benefits

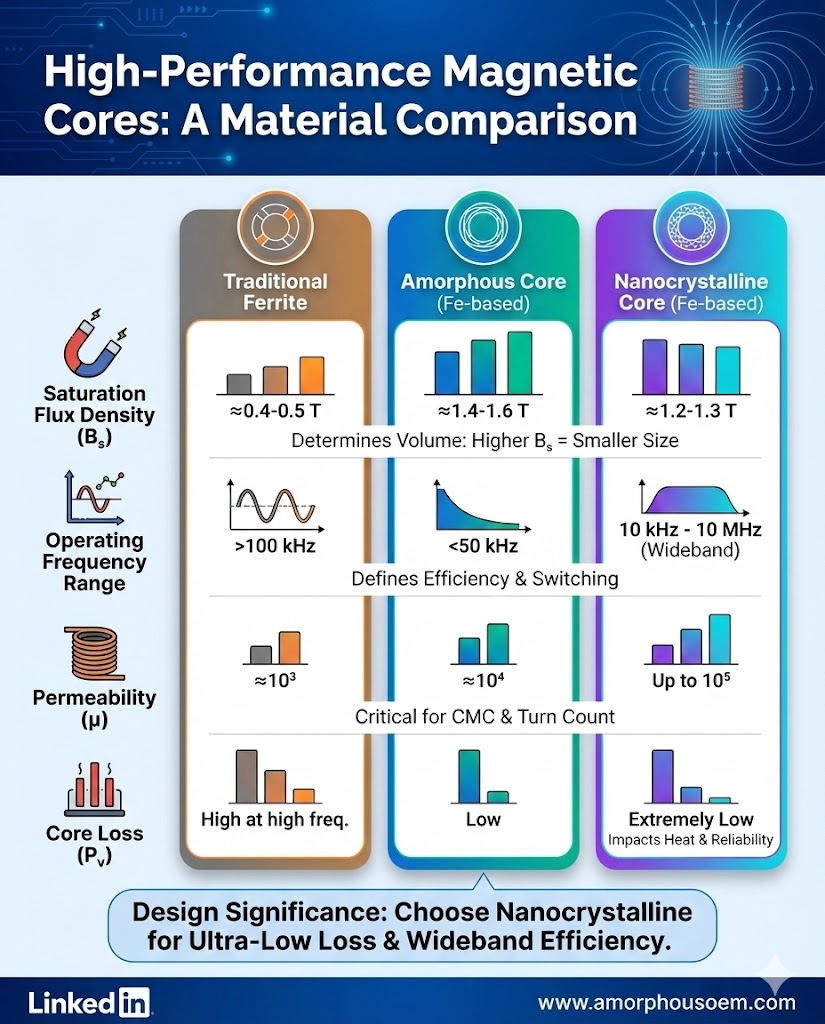

High Saturation Induction (Bs = 1.25T): significantly higher than Ferrite (~0.4T), preventing saturation under high current spikes and allowing for volume reduction.

Superior Inductance: Tested at minimum 100.0 μH (1kHz, 0.3V), providing excellent broadband attenuation for EMI suppression.

Thermal Robustness: The core material is stable up to 570°C, while the robust PBT housing ensures reliable operation and insulation up to 140°C.

Protective Packaging: Encapsulated in a square, top-seam Black PBT casing (UL94-V0 equivalent material) to protect the nanocrystalline ribbon from mechanical stress and ensure consistent electrical performance.

Applications

Automotive: EV On-Board Chargers (OBC), DC/DC Converters, and Motor Drive filtering.

Power Supplies: High-power Switching Mode Power Supplies (SMPS) and UPS systems.

Renewable Energy: Solar Inverters and Wind Power Converters requiring high efficiency and compact design.

[Note: Custom sizes and inductance values are available upon request.]

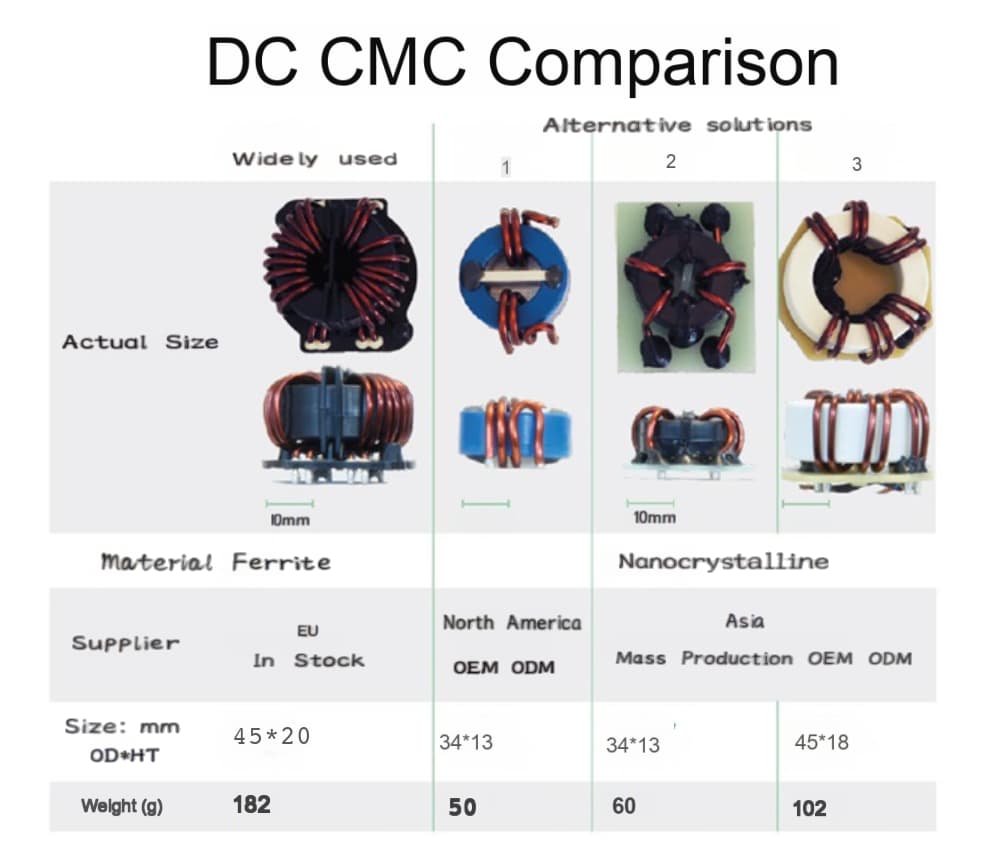

Nanocrstelline Inductors VS Ferrite Inductors in Size and Weight Case Study:

AC Common Mode Choke:

📉 62% Weight Reduction

📉 54% Volume Reduction

🌡️ Cooler Operation: 6°C lower temp rise compared to ferrite.

DC Common Mode Choke:

📦 Core weight and volume reduced to 1/3 of the original design.

⚡ significantly higher impedance and better thermal stability.

💰 The Economic Reality (TCO): Many engineers worry about the initial material cost. Our case study shows:

Efficiency Gains: 5% - 27% improvement depending on load.

ROI: The slightly higher component cost is recovered in 1-4 years through energy savings.

System Savings: Smaller cores mean smaller PCBs, lighter cooling systems, and increased payload for commercial vehicles.

Quick View for Material comparison