JHNO71.5*29.6*30 Nanocrystalline Common Mode Choke Core for EV Power Units

Engineered for automotive EV/HEV applications, this high-performance Nanocrystalline core delivers superior EMI suppression for On-Board Chargers (OBC) and DC/DC converters. Featuring a high saturation flux density (Bs=1.25T) and extreme thermal stability, it allows engineers to downsize magnetic components while maintaining high impedance across a wide frequency range (-40°C to +140°C).

Item No :

JHNO 71.5*29.6*30Order(MOQ) :

Flexible, Adjust based on customer requirementsCertification :

IATF16949, ISO9001, RoHSTrademark :

JHOrigin :

ChinaHS Code :

8504909000 ( Cores) or 8504500000 (Inductors)Production Capacity :

2,000,000 / Month

The JHNO71.5*29.6*30 is a premium toroidal core designed to solve the toughest thermal and EMI challenges in modern electric vehicles. Unlike traditional Ferrite cores, our 1K107 Nanocrystalline material maintains stable magnetic permeability even under extreme engine compartment temperatures (Tc = 560 degree).

With a large window area (Aw = 1332 mm2), this core is optimized for high-current windings, making it the ideal solution for common mode chokes in high-power automotive power electronics.

Automotive: EV On-Board Chargers (OBC), DC/DC Converters, Motor Drivers.

Charging Infrastructure: DC Fast Charging Stations.

Industrial: High-power SMPS, VFDs, and Renewable Energy Inverters.

Core Material: Fe-based Nanocrystalline 1K107

| Saturate induction / Bs (T) | 1.25 | Saturation Magnetostriction (λs) | 2.0 |

| Curie temperature Tc (℃) | 560 | Density ρ (g/cm³) | 7.2 |

| Crystalline temp. Tx (℃) | 510 | Resistivity δ ( μΩ.cm) | 100 |

| Hardness Hv | 880 | Ribbon Thickness (μm) | 14~20 |

| Initial permealbility (μi) | 80,000 | Stacking factor | ≥ 0.75 |

| Working temperature Tc (℃) | -40~140 |

| Inductance | Turns | Test Condition | Test Equipment |

|---|---|---|---|

| Z=100 μH MIN | 1Ts | 10KHz/0. 3V, 100Ω , 25±5℃ | ZX8516B or Equivalent |

[Note: Custom sizes and inductance values are available upon request.]

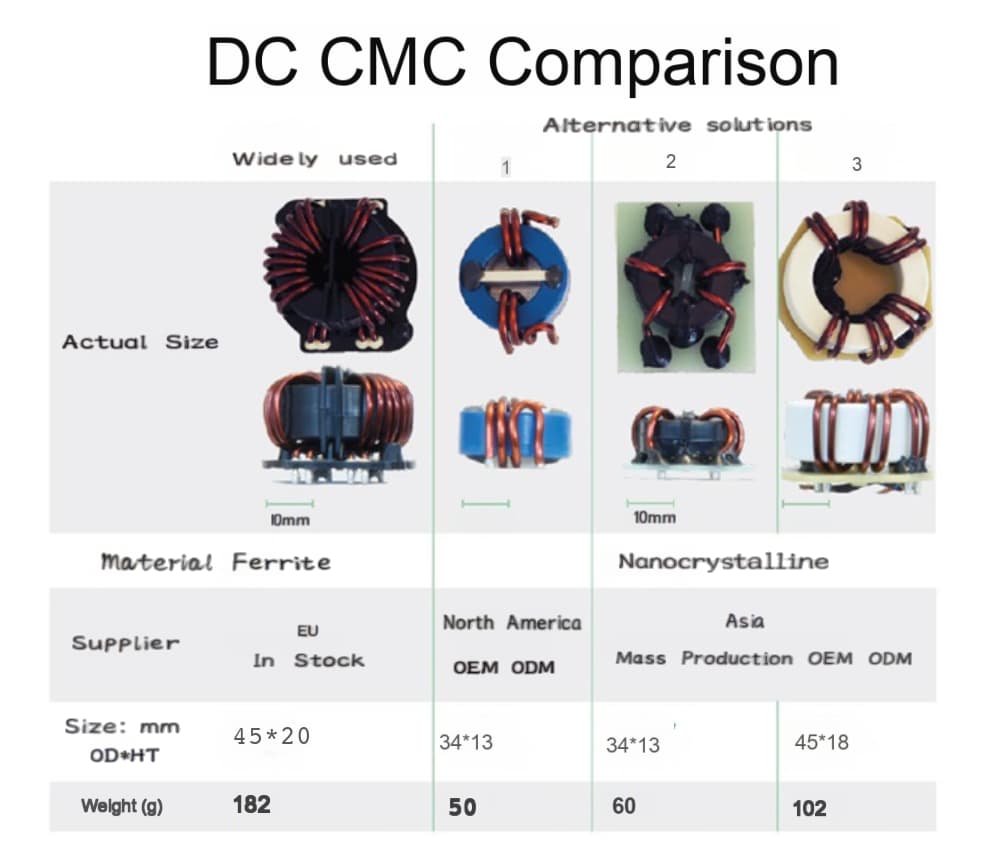

Nanocrstelline Inductors VS Ferrite Inductors in Size and Weight Case Study:

AC Common Mode Choke:

📉 62% Weight Reduction

📉 54% Volume Reduction

🌡️ Cooler Operation: 6°C lower temp rise compared to ferrite.

DC Common Mode Choke:

📦 Core weight and volume reduced to 1/3 of the original design.

⚡ significantly higher impedance and better thermal stability.

💰 The Economic Reality (TCO): Many engineers worry about the initial material cost. Our case study shows:

Efficiency Gains: 5% - 27% improvement depending on load.

ROI: The slightly higher component cost is recovered in 1-4 years through energy savings.

System Savings: Smaller cores mean smaller PCBs, lighter cooling systems, and increased payload for commercial vehicles.

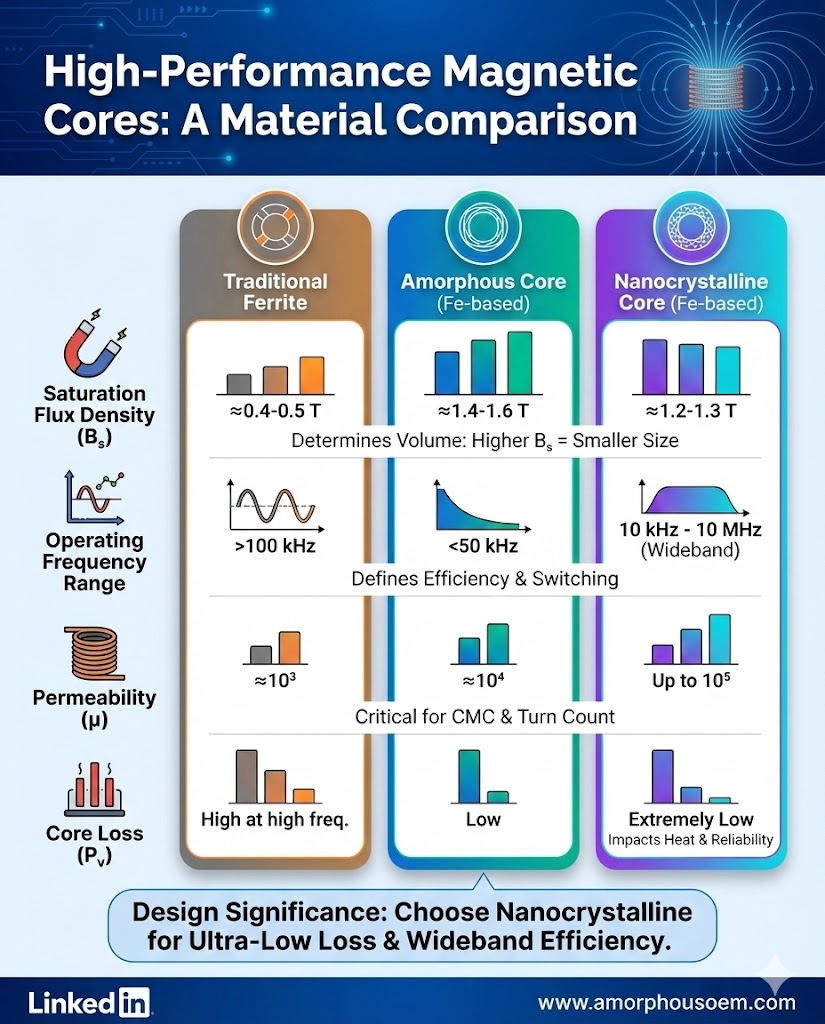

Quick View for Material comparison