Jan 11, 2026

In the competitive landscape of European automotive electronics, thermal management and EMI compliance are the twin hurdles every engineer must clear. Recently, a prominent Tier-1 manufacturer of On-Board Chargers (OBC) based in Turin, Italy, approached us with a critical design bottleneck.

This case study details how switching from Ferrite to our Iron-based Nanocrystalline Core (54.0x 50.5 x 18.0 mm) helped them downsize their 22kW charging module while surviving extreme engine compartment temperatures.

The Challenge: Saturation at High Temperatures

The Italian engineering team was designing a high-density DC/DC converter stage for a new electric hypercar. They faced two specific problems using traditional Mn-Zn Ferrite cores:

Thermal Derating: At the target operating temperature of 120°C, the Ferrite cores were losing significant permeability, leading to EMI filter failure.

Size Constraints: To prevent magnetic saturation under high current spikes, they had to stack multiple ferrite cores, which violated the strict height restriction of the OBC housing.

They needed a solution that offered high saturation flux density (Bs) and stable inductance in a compact footprint.

The Solution: High Bs Nanocrystalline Technology

After reviewing their magnetic circuit requirements, we proposed our Nanocrystalline Toroidal Core (Model: 54.0).

Here is why this specific core was the perfect fit for their application:

1.25T Saturation Flux Density (Bs): Unlike Ferrite (Bs ~0.4T), our iron-based nanocrystalline material handles three times the flux density. This allowed the Italian team to replace two stacked ferrite cores with a single Nanocrystalline unit, reducing weight and volume immediately.

Extreme Thermal Stability: With a Curie Temperature of 570°C and a crystallization temperature of 510°C, the core’s magnetic properties remain virtually unchanged from -40°C to +140°C.

Superior Inductance per Turn: The core delivers an AL value of ≥ 100.0 µH (at 1kHz, 0.3V). This high impedance allowed the engineers to achieve the required Common Mode attenuation with fewer wire turns, further reducing copper loss (I²R).

Robust Packaging for Automotive Standards

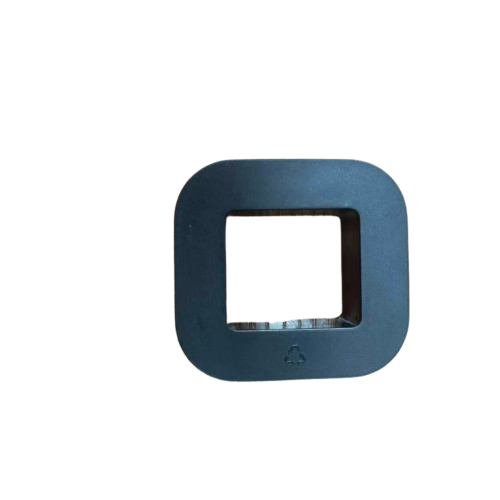

Reliability is non-negotiable in the EU market. The Italian client was particularly impressed with the encapsulation. The core is housed in a Square-Top Seam Black PBT Case (Polybutylene Terephthalate).

Material: UL94-V0 rated PBT.

Temperature Rating: Certified for continuous operation up to 140°C.

Mechanical Protection: The rigid case protects the delicate nanocrystalline ribbons from winding stress, ensuring the mechanical pressure does not degrade the magnetic permeability (magnetostriction effect).

The Result: Successful EMC Certification

By integrating the 54.0mm Nanocrystalline core, the client successfully:

Reduced Component Height: Met the 20mm clearance requirement (Core height is 18.0mm).

Passed CISPR 25 Class 5: The high permeability at 10kHz–150kHz solved their low-frequency noise issues.

Enhanced Durability: The effective cross-sectional area (Ae = 168.48 mm²) provided robust performance without saturation during load dump transients.

ConclusionFor power electronics engineers struggling with space constraints and high-temperature environments, traditional materials often fall short. As proven by our Italian partners, switching to High-Bs Nanocrystalline cores is not just an upgrade—it is a necessity for next-gen EV power electronics.

Looking for high-performance magnetic cores? Check our full datasheet for the 54.0mm series or contact our engineering team for custom samples.

For more details, check: https://www.amorphousoem.com/product/jhno-nanocrystalline-common-mode-choke-core-for-ev-power-units

Read More